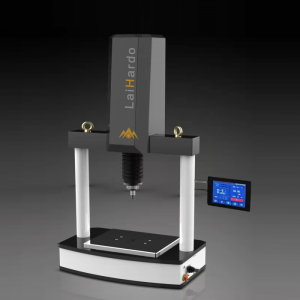

Isivivinyo Sokuqina Kobulukhuni Sedijithali Esihlanganisiwe Se-HBRVT-187.5

*Isihloli sokuqina se-HBRVS-187.5T Digital Brinell Rockwell & Vickers sifakwe isikrini esikhulu esisanda kuklanywa esinokwethenjelwa okuhle, ukusebenza okuhle kakhulu kanye nokubukwa okulula, ngakho-ke siwumkhiqizo wobuchwepheshe obuphezulu ohlanganisa izici ze-optic, mechanic kanye ne-electric.

*Inezindlela ezintathu zokuhlola zikaBrinell, Rockwell kanye noVickers kanye namazinga ayi-7 amandla okuhlola, angahlola izinhlobo eziningana zobulukhuni.

*Ukuhlola amandla okulayisha, ukuhlala, ukulayisha kusebenzisa ukushintsha okuzenzakalelayo ukuze kube lula futhi kusheshe ukusebenza.

*Ingabonisa futhi isethe isikali samanje, amandla okuhlola, i-test indenter, isikhathi sokuhlala kanye nokuguqulwa kobulukhuni;

*Umsebenzi oyinhloko umi kanje: Ukukhetha izindlela ezintathu zokuhlola zeBrinell, Rockwell kanye neVickers; Izikali zokuguqulwa zezinhlobo ezahlukene zobulukhuni; Imiphumela yokuhlolwa ingagcinwa ukuze ihlolwe noma iphrintwe, ukubalwa okuzenzakalelayo kwenani eliphezulu, elincane kanye neliphakathi; Nge-interface ye-RS232 yokuxhuma kwikhompyutha.

Ifanele insimbi eqinile neyomile ebusweni, insimbi eqinile ye-alloy, izingxenye zokuphonsa, izinsimbi ezingezona i-ferrous, izinhlobo ezahlukene zensimbi eqinile neyomile kanye nensimbi ethambile, ishidi lensimbi elifakwe i-carburized, izinsimbi ezithambile, izinto zokwelapha ukushisa komhlaba kanye nezinto zokwelapha ngamakhemikhali njll.

Amandla Okuhlola eRockwell: 60kgf (588.4N), 100kgf (980.7N), 150kgf (1471N)

Amandla Okuhlola eBrinell: 30kgf (294.2N), 31.25kgf (306.5N), 62.5kgf (612.9N), 100kgf (980.7N), 187.5kgf (1839N)

Amandla Okuhlola eVickers: 30kgf (294.2N), 100kgf (980.7N) I-Indenter:

I-Diamond Rockwell Indenter, i-Diamond Vickers Indenter,

Ukufundwa kobulukhuni be-Ball Indenter ф1.588mm, ф2.5mm, ф5mm: Isibonisi Sesikrini Sokuthinta

Isikali Sokuhlola: HRA, HRB, HRC, HRD, HBW1/30, HBW2.5/31.25, HBW2.5/62.5, HBW2.5/187.5, HBW5/62.5, HBW10/100, HV30, HV100

Isikali Sokuguqulwa:HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRK, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T,

Ukukhulisa: Brinell: 37.5×, Vickers: 75×

Iyunithi Yokulinganisa Encane: Brinell: 0.5μm, Vickers: 0.25μm

Ukulungiswa kobulukhuni: Rockwell: 0.1HR, Brinell: 0.1HBW, Vickers: 0.1HV

Isikhathi Sokuhlala: 0 ~ 60s

Ukuphakama Okuphezulu Kwesifanekiso:

I-Rockwell: 230mm, i-Brinell: 150mm, i-Vickers: 165mm,

Umphimbo: 165mm

Ukukhishwa Kwedatha: Iphrinta Eyakhelwe Ngaphakathi, I-RS232 Interface

Ukunikezwa Kwamandla: AC220V,50Hz

Sebenzisa Okujwayelekile:

I-ISO 6508,ASTM E18,JIS Z2245,GB/T 230.2 ISO 6506,ASTM E10,JIS Z2243,GB/T 231.2 ISO 6507,ASTM E92,JIS Z2244,GB/T 4340.2

Ubukhulu: 475×200×700mm,

Isisindo Esiphelele: 70kg, Isisindo Esiphelele: 90kg

| Igama | Ubuningi | Igama | Ubuningi |

| Umzimba Oyinhloko Wezinsimbi Zomculo | Isethi e-1 | I-Diamond Rockwell Indenter | 1 i-pc |

| I-Diamond Vickers Indenter | 1 i-pc | I-F1.588mm, F2.5mm, F5mm I-Ball Indenter | i-pc eyodwa ngayinye |

| Ithebula Lokuhlola Elishelele | 1 i-pc | Ithebula Lokuhlola Lendiza Ephakathi | 1 i-pc |

| Ithebula Lokuhlola Lendiza Elikhulu | 1 i-pc | Ithebula Lokuhlola Elinomumo Ofana No-V | 1 i-pc |

| I-Eyepiece Yokulinganisa Yedijithali engu-15 × | 1 i-pc | Inhloso engu-2.5×, 5× | i-pc eyodwa ngayinye |

| Uhlelo lwe-Microscope (faka ukukhanya kwangaphakathi nokukhanya kwangaphandle) | Isethi e-1 | Ibhulokhi Lokuqina 150~250 HB W 2.5/187.5 | 1 i-pc |

| Ibhulokhi Lokuqina 60~70 HRC | 1 i-pc | Ibhulokhi Lokuqina 20~30 HRC | 1 i-pc |

| Ibhulokhi Lokuqina 80~100 HRB | 1 i-pc | Ibhulokhi Yokuqina 700~800 HV 30 | 1 i-pc |

| Uhlelo lokulinganisa izithombe ze-CCD | Isethi e-1 | Ikhebula Lamandla | 1 i-pc |

| Incwadi Yemiyalelo Yokusebenzisa | Ikhophi eyodwa | Ikhompyutha (Ongakukhetha) | 1 i-pc |

| Isitifiketi | Ikhophi eyodwa | Isembozo Esilwa Nothuli | 1 i-pc |

UVickers:

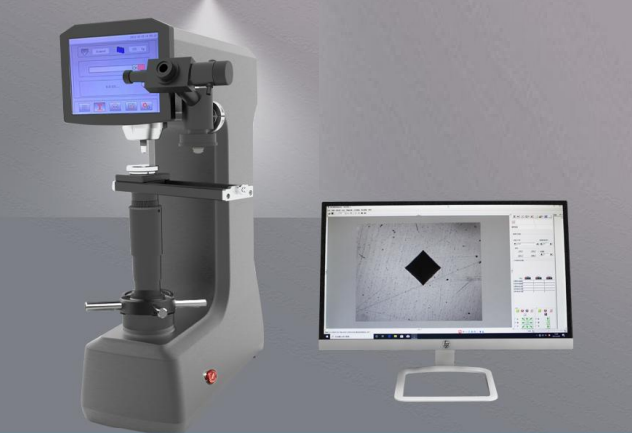

* Uhlelo lokucubungula isithombe lwe-CCD lungaqeda inqubo ngokuzenzakalelayo: ukukalwa kobude obuqondile bokugoba, ukubonisa inani lobulukhuni, ukuhlola idatha kanye nokulondolozwa kwesithombe, njll.

* Iyatholakala ukuze kusethwe kusengaphambili umkhawulo ophezulu nophansi wenani lobulukhuni, umphumela wokuhlola ungahlolwa ukuthi ngabe uyafaneleka ngokuzenzakalelayo.

* Qhubeka nokuhlola ubulukhuni kumaphuzu okuhlola angu-20 ngesikhathi esisodwa (setha ibanga eliphakathi kwamaphuzu okuhlola ngokuthanda kwakho), bese ulondoloza imiphumela yokuhlola njengeqembu elilodwa.

* Ukuguqula phakathi kwezikali zobulukhuni ezahlukene kanye namandla okuqina

* Buza idatha egciniwe nesithombe nganoma yisiphi isikhathi

* Ikhasimende lingalungisa ukunemba kwenani lobunzima elilinganisiwe nganoma yisiphi isikhathi ngokuya ngokulinganiswa kwe-Hardness Tester

* Inani le-HV elilinganisiwe lingaguqulwa libe ezinye izikali zobulukhuni (HB,HRnjll)

* Uhlelo luhlinzeka ngesethi ecebile yamathuluzi okucubungula izithombe kubasebenzisi abathuthukile. Amathuluzi ajwayelekile ohlelweni afaka phakathi ukulungisa ukuKhanya, ukuQondanisa, iGamma, kanye neZinga le-Histogram, kanye nemisebenzi ye-Sharpen, Smooth, Invert, kanye ne-Convert ibe yi-Grey. Ezithombeni zesikali esimpunga, uhlelo luhlinzeka ngamathuluzi ahlukahlukene athuthukile ekuhlungeni nasekutholeni imiphetho, kanye namanye amathuluzi ajwayelekile ekusebenzeni kwesimo somzimba njenge-Open, Close, Dilation, Erosion, Skeletonize, kanye ne-Flood Fill njll.

* Uhlelo luhlinzeka ngamathuluzi okudweba nokukala izimo ezivamile zejometri ezifana nemigqa, ama-engeli anamaphuzu angu-4 (ama-vertex angekho noma afihliwe), ama-ractangle, imibuthano, ama-ellipses, nama-polygons. Qaphela ukuthi ukulinganisa kucabanga ukuthi uhlelo lulinganisiwe.

* Uhlelo luvumela umsebenzisi ukuphatha izithombe eziningi ku-albhamu ezingalondolozwa futhi zivulwe kusuka kufayela le-albhamu. Izithombe zingaba nezimo zejometri ezijwayelekile kanye namadokhumenti njengoba afakwe ngumsebenzisi njengoba kuchaziwe ngenhla.

Esithombeni, uhlelo luhlinzeka ngomhleli wedokhumenti ukuze afake/ahlele amadokhumenti anokuqukethwe kungaba ngefomethi yokuhlola elula noma ngefomethi ye-HTML ethuthukisiwe enezinto ezifaka amathebhu, uhlu, nezithombe.

*Isistimu ingaphrinta isithombe ngokukhulisa okucacisiwe ngumsebenzisi uma silinganisiwe.

Ingasetshenziswa ukunquma ubulukhuni bensimbi ye-Vickers, izinsimbi ezingezona i-ferrous, izinto zobumba, izendlalelo ezilungisiwe zobuso bensimbi, kanye nezigaba zobulukhuni bezendlalelo zensimbi ezifakwe i-carburized, nitrided kanye neziqinisiwe. Kuyafaneleka futhi ukunquma ubulukhuni bezingxenye ezincane nezincane kakhulu ze-Vickers.

UBrinell:

1. Ukulinganisa okuzenzakalelayo: Thatha ngokuzenzakalelayo ukugoba bese ulinganisa ububanzi bese ubala inani elihambisanayo lobunzima bukaBrinell;

2. Ukulinganisa ngesandla: Kala ngesandla ukugoba, uhlelo lubala inani elihambisanayo lobunzima bukaBrinell;

3. Ukuguqulwa kobulukhuni: Uhlelo lungaguqula inani lobulukhuni le-Brinell elilinganisiwe i-HB libe elinye inani lobulukhuni njenge-HV, i-HR njll.;

4. Izibalo zedatha: Uhlelo lungabala ngokuzenzakalelayo inani elimaphakathi, ukuhlukahluka kanye nelinye inani lezibalo lobunzima;

5. I-alamu ejwayelekile edlula: Maka ngokuzenzakalelayo inani elingavamile, lapho ubulukhuni budlula inani elibekiwe, buxwayisa ngokuzenzakalelayo;

6. Umbiko wokuhlola: Khiqiza ngokuzenzakalelayo umbiko wefomethi ye-WORD, amathempulethi ombiko angashintshwa ngumsebenzisi.

7. Isitoreji sedatha: Idatha yokulinganisa ehlanganisa isithombe sokufakwa ngaphakathi ingagcinwa kufayela.

8. Eminye imisebenzi: ifaka yonke imisebenzi yokucubungula izithombe kanye nesistimu yokulinganisa, njengokuthwebula izithombe, ukulinganisa, ukucubungula izithombe, ukulinganisa kwejometri, isichasiselo, ukuphathwa kwe-albhamu yezithombe kanye nokuphrinta kwezikhathi ezimisiwe njll.