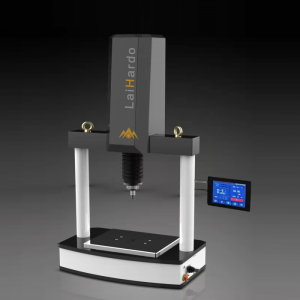

Isivivinyo Sokuqina Kwe-Rockwell Yedijithali ye-HRS-150ND (Uhlobo Lwekhala Eligobile)

Ama-HRSIsihloli sokuqina kwempumulo esi-convex esingu-150ND i-Rockwell sisebenzisa isibonisi sakamuva sesikrini sokuthinta se-TFT esingu-5.7-intshi, ukushintshashintsha kwamandla okuhlola okuzenzakalelayo; ukubonisa okuqondile kokujula okusele h ngokuya ngezidingo zesitifiketi se-CANS kanye ne-Nadcap; ingabuka idatha eluhlaza ngamaqembu nasemaqenjini; idatha yokuhlola ingaphrintwa yiqembu ngephrinta yangaphandle ongayikhetha, noma isofthiwe yokulinganisa ikhompyutha ye-Rockwell engayikhetha ingasetshenziswa ukuqoqa idatha yokuhlola ngesikhathi sangempela. Ifanele ukunqunywa kokuqina kokucima, ukufudumala, ukupholisa, ukupholisa okubandayo, ukupholisa okungaguquki, insimbi ye-carbide, i-aluminium alloy, i-copper alloy, insimbi yokuthwala, njll.

Lo mkhiqizo usebenzisa isakhiwo esikhethekile se-indenter (esaziwa kakhulu ngokuthi isakhiwo "sekhala eliyi-convex"). Ngaphezu kokuhlolwa okungaqedwa ngumhloli wokuqina wendabuko we-Rockwell, ungahlola futhi izindawo ezingenakulinganiswa ngumhloli wokuqina wendabuko we-Rockwell, njengobuso bangaphakathi bezingxenye ezi-annular neze-tubular, kanye nobuso bendandatho yangaphakathi (i-indenter emfushane ongayikhetha, ububanzi obuncane bangaphakathi bungaba ngu-23mm); unezici zokunemba okuphezulu kokuhlolwa, ububanzi bokulinganisa obubanzi, ukulayisha okuzenzakalelayo kanye nokuthululwa kwamandla okuhlola ayinhloko, ukuboniswa kwedijithali kwemiphumela yokulinganisa kanye nokuphrinta okuzenzakalelayo noma ukuxhumana namakhompyutha angaphandle. Kukhona nemisebenzi enamandla yokusiza, njenge: izilungiselelo zomkhawulo ophezulu nophansi, i-alamu yokwahlulela engabekezeleleki; izibalo zedatha, inani elimaphakathi, ukuphambuka okujwayelekile, amanani aphezulu naphansi; ukuguqulwa kwesikali, okungaguqula imiphumela yokuhlolwa ibe amanani e-HB, HV, HLD, HK kanye namandla e-Rm; ukulungiswa kobuso, ukulungiswa okuzenzakalelayo kwemiphumela yokulinganisa eyindilinga neyesiyingi. Kusetshenziswa kabanzi ekutholeni, ocwaningweni lwesayensi nasekukhiqizweni kokulinganisa, ukukhiqizwa kwemishini, i-metallurgy, imboni yamakhemikhali, izinto zokwakha kanye neminye imboni.

| imodeli | Ama-HRS-150ND |

| Amandla okuqala okuhlola eRockwell | 10kgf(98.07N) |

| Amandla okuhlola aphelele eRockwell | 60kgf(588N) 100kgf(980N) 150kgf(1471N) |

| Isikali Sokuqina Kwe-Rockwell | I-HRA, i-HRB, i-HRC, i-HRD, i-HRE, i-HRF, i-HRG, i-HRH, i-HRK, i-HRL, i-HRM, i-HRR, i-HRP, i-HRS, i-HRV |

| Uhla lokuhlola lweRockwell | HRA: 20-95 , HRB: 1 0-100, HRC: 1 0-70, HRD: 40-77, HRE: 70-100, HRF: 60-100, HRG: 30-94, HRH: 80-100, HRK000-50:1-HRM: 50-10:1-3 HRE 0 -115, HRR: 50-115 |

| Hlola ukushintsha kwamandla | Ukushintsha okuzenzakalelayo kwe-Stepper motor |

| Ukulungiswa kwenani lokuqina | 0.1 / 0.01HR ozikhethela |

| umbukiso | Isikrini sokuthinta sesibonisi se-TFT esingu-5.7-intshi, isikhombikubona se-UI esinembile |

| Ukujula okusele kokugoba | Isibonisi sesikhathi sangempela |

| Umbhalo Wemenyu | IsiShayina/IsiNgisi |

| Indlela yokusebenza | Isikrini sokuthinta se-TFT |

| Inqubo Yokuhlola | Ukuqedela okuzenzakalelayo ngemiyalezo yombhalo |

| Isikhathi sokulayisha samandla okuhlola ayinhloko | Imizuzwana emi-2 kuya kweyi-8 ingasethwa |

| Isikhathi sokuhlala | 0-99s, futhi ingabeka futhi igcine isikhathi sokuqala sokubamba amandla okuhlola, isikhathi sokubamba amandla okuhlola esiphelele, isikhathi sokubamba sokubuyisa okunwebekayo, isikhathi sokubonisa esihlukaniswe ngezigaba; ihambisana nokubala phansi kokushintsha kombala |

| Ukufinyeleleka | Izilungiselelo zomkhawulo ophezulu nophansi, i-alamu yokwahlulela engabekezeleleki; izibalo zedatha, inani elimaphakathi, ukuphambuka okujwayelekile, inani eliphakeme, inani eliphansi; ukuguqulwa kwesikali, imiphumela yokuhlolwa ingaguqulwa ibe yi-Brinell HB, i-Vickers HV, i-Leeb HL, ubulukhuni be-surface Rockwell kanye namandla okunamathela i-Rm/Ksi; ukulungiswa kobuso, ukulungiswa okuzenzakalelayo kwemiphumela yokulinganisa eyindilinga neyesiyingi |

| Sebenzisa izindinganiso zakamuva | GB/T230-2018, ISO6508, ASTM E18, BSEN10109, ASTM E140, ASTM A370 |

| Isikhala esiphezulu sokuhlola | 270mm ngokuvundlile, 155mm ngokuvundlile |

| Uhlobo lwezingxenye zokuhlola | Ubuso obuyisicaba; ubuso obuyindilinga, ububanzi obuncane bangaphandle obungu-3mm; ubuso bendandatho yangaphakathi, ububanzi obuncane bangaphakathi obungu-23mm |

| Umthamo wokugcina idatha | Amaqembu angu-≥1500 |

| Ukuphequlula idatha | Ungaphequlula ngeqembu kanye nedatha enemininingwane |

| Ukuxhumana Kwedatha | Ingaxhunywa kuphrinta encane nge-port ye-serial (iphrinta ongayikhetha);Ukudluliswa kwedatha kungenziwa nge-PC nge-serial port (isofthiwe yokulinganisa ikhompyutha ye-Rockwell host ongayikhetha) |

| ukunikezwa kwamandla kagesi | 220V/110V, 50Hz, 4A |

| usayizi | 715mm × 225mm × 790mm |

| isisindo sengqikithi | 100kg |

| igama lithi | inani lenombolo | igama lithi | inani lenombolo |

| Ithuluzi Lomculo | Iyunithi e-1 | I-Diamond Rockwell Indenter | 1 |

| Ibhola le-φ1.588mmi-indenter | 1 | Ibhentshi lokuhlola eliyindilinga, ibhentshi lokuhlola elinomfanekiso ongu-V | 1 ngayinye |

| Ibhulokhi yokuqina ejwayelekile i-HRA | Ibhulokhi eli-1 | Ibhulokhi yokuqina ejwayelekile i-HRBW | Ibhulokhi eli-1 |

| Ibhulokhi yokuqina ejwayelekile i-HRC | Izingcezu ezi-3 | Isikulufu sokufaka ikhanda lokucindezela | 2 |

| Intambo kagesi | Impande e-1 | Isikulufu sokulungisa izinga | 4 |

| Isembozo sothuli | 1 | Isitifiketi Somkhiqizo | Ukuphakelwa okungu-1 |

| Incwajana Yomkhiqizo | Ukuphakelwa okungu-1 |

|