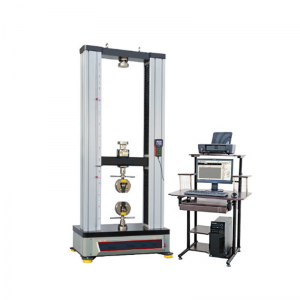

Isivikelo Sokukhiya Isikrini Sokuthinta Esizenzakalelayo se-Rockwell kanye ne-Rockwell Engacacile

1. Ukuthembeka okuhle, ukusebenza okuhle kakhulu nokubuka okulula;

2. Iqhutshwa ngogesi, isakhiwo esilula, akukho sisindo esisetshenziswayo.

3. Ingaxhuma i-PC kokukhiphayo

4. Ukuguqulwa kwezikali zobulukhuni ezahlukene;

Lo modeli wokuhlola ubulukhuni ufanelekela ukucima, ukucima kanye nokushisa, ukubopha, ukubopha okubandayo, ukubopha okuthambile, ukunqunywa kobulukhuni bensimbi eqinile, i-aluminium alloy, i-copper alloy, insimbi ethwala, njll. Ifaneleka futhi nensimbi eqinile ebusweni, ukwelashwa kokushisa kwendawo yezinto ezibonakalayo kanye nesendlalelo sokwelashwa ngamakhemikhali, ithusi, i-aluminium alloy, ipuleti elincane, i-galvanized, i-chrome plated, impahla eboshwe nge-tin, insimbi ethwala, ukubopha okubandayo, njll.

1. Iqhutshwa ngogesi esikhundleni sesisindo, Isiteji siyaphakama futhi sehle ngokuzenzakalelayo, bese umsebenzi uphakama ngokhiye owodwa, i-indenter iyalayishwa, inakekelwe, futhi ithululwe, inani lobulukhuni liyaboniswa, bese isigaba sibuyela ngokuzenzakalelayo endaweni yokuqala.

2. Isikrini esibonakalayo esilula sokuthinta, isikhombikubona sokusebenza esenziwe umuntu;

3. Ukuthululwa komzimba oyinhloko womshini, ukuguqulwa kohlaka kuncane, inani lokulinganisa lizinzile futhi lithembekile;

4. Umsebenzi onamandla wokucubungula idatha, ungahlola izinhlobo ezingu-15 zezikali zobulukhuni beRockwell, futhi ungaguqula i-HR, i-HB, i-HV kanye nezinye izindinganiso zobulukhuni;

5. Igcina idatha yamasethi angu-500 ngokuzimela, futhi idatha izogcinwa uma ugesi ucishiwe;

6. Isikhathi sokuqala sokubamba umthwalo kanye nesikhathi sokulayisha singasethwa ngokukhululeka;

7. Imikhawulo ephezulu nephansi yobulukhuni ingasethwa ngqo, ukubonisa okufanelekile noma cha;

8. Ngomsebenzi wokulungisa inani lobulukhuni, isikali ngasinye singalungiswa;

9. Inani lobulukhuni lingalungiswa ngokuya ngobukhulu besilinda;

10. Landela izindinganiso zakamuva ze-ISO, ASTM, GB kanye nezinye.

Ububanzi bokulinganisa: 20-88HRA, 20-100HRB, 20-70HRC

Amandla okuqala okuhlola :3kgf (29.42N), 10kgf (98.07N)

Amandla okuhlola aphelele: 15kgf (147.1N), 30kgf (294.2N), 45kgf (441.3N),60kgf (558.4N), 100kgf (980.7N), 150kgf (1471N)

Ukuphakama okuphezulu kwesampula: 230mm

Umphimbo: 170mm

I-Indenter: I-Rockwell diamond indenter, i-ф1.588mm steel ball indenter

Indlela yokusebenzisa amandla okuhlola: okuzenzakalelayo (ukulayisha/ukuhlala/ukukhulula)

Isixazululo sobulukhuni: 0.1HR

Imodi yokubonisa inani lokuqina: Isikrini sokuthinta siyaboniswa

Izikali zokulinganisa: HRA, HRD, HRC, HRF, HRB, HRG, HRH, HRE, HRK, HRL, HRM, HRP, HRR, HRS, HRV

Isikali sokuguqulwa: HV, HK, HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRK, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HS, HBW

Ukukhishwa kwedatha: isikhombimsebenzisi se-RS232

Sebenzisa Okujwayelekile: ISO 6508,ASTM E-18,JIS Z2245,GB/T 230.2

Ukunikezwa kwamandla: I-AC 220V/110V, 50/60 Hz

Ubukhulu: 475 x 200 x 700 mm

Isisindo: isisindo esiphelele cishe ngo-60KG, isisindo esiphelele cishe ngo-80KG

| Umshini Oyinhloko | Isethi eli-1 | I-Indenter yebhola le-ф1.588mm | 1 i-PC |

| I-Indenter ye-Diamond Cone | 1 i-PC | Iphrinta | 1 i-PC |

| I-Anvil (Enkulu, Ephakathi, Enesimo "se-V") | ISAMBA 3 PCS | I-adaptha | 1 i-PC |

| Ibhulokhi Yokuqina Ejwayelekile yeRockwell | Ikhebula Lamandla | 1 i-PC | |

| I-HRB | 1 i-PC | Ikhebula le-RS-232 | 1 i-PC |

| I-HRC (Phezulu, Phansi) | ISAMBA 2 PCS | I-Spanner | 1 i-PC |

| Ibhulokhi yokuqina okungabonakali | ISAMBA 2 PCS | Uhlu lokupakisha | Ikhophi eyodwa |

| Isitifiketi | Ikhophi eyodwa |