I-LHMICV5100 I-Microscope Eqondile Ezenzakalelayo Ngokugcwele

Yonke imisebenzi yaklanywa ngokwemigomo ye-ergonomics ukunciphisa ukukhathala komqhubi. Ukwakheka kwayo kwezingxenye ze-modular kuvumela ukuhlanganiswa okuguquguqukayo kwemisebenzi yesistimu. Ihlanganisa imisebenzi ehlukahlukene yokubuka, kufaka phakathi i-bright-field, i-dark-field, ukukhanya okuqondile, ukukhanya okuhlanganisiwe, kanye ne-DIC differential interferometry, kanye nemisebenzi ekhethwayo ngokusekelwe kuzinhlelo zokusebenza ezithile.

Isekela insimu yokubuka ebanzi kakhulu engu-25mm ehamba phambili emhlabeni, ikulethela ulwazi olusha lokubuka olubanzi. Uhlu olubanzi lokulungiswa kwe-diopter lungahlangabezana nezidingo zabasebenzisi abaningi kuzinhlelo zokusebenza ezithile.

Izinhloso ze-semi-apochromatic ze-bright-field kanye ne-dark-field zenziwe ngamalensi akhethwe ngokucophelela aphezulu okudlulisa kanye nobuchwepheshe obuthuthukisiwe bokumboza ukuze kuphinde kuvele imibala yemvelo yesampula; umklamo we-semi-apochromatic unokusebenza okuhle kakhulu kokulungisa umbala, okuthuthukisa ukungafani kanye nokucaca kwesithombe esibonwayo.

Uhlelo lwe-polarization luhlanganisa i-polarizer insert kanye ne-analyzer insert, engenza ukutholwa kokukhanya oku-polarized. Ekuhlolweni kwe-semiconductor kanye ne-PCB, lungasusa ukukhanya okulahlekile futhi lwenze imininingwane icace.

I-analyzer ejikelezayo engu-360° ivumela ukubonwa okulula kokubonakala kwesampula ngaphansi kokukhanya ngama-engeli ahlukene e-polarization ngaphandle kokuhambisa isampula.

● Isigaba se-XY esinenjini enembile kakhulu, esihlanganiswe nohlelo lokulawula oluvaliwe, senza kube lula ukuskena isithombe esinosayizi ogcwele kanye nokuhlanganiswa kwesithombe esisebenza kahle, okuqinisekisa ukuhlanganiswa okungenamthungo kwezinkambu eziningi zokubuka.

● Isekela izindlela zokuskena ezenziwe ngokwezifiso, ivumelana namasampula angajwayelekile, futhi ithuthukisa izinga lempumelelo lokuhlanganisa izindawo eziyinkimbinkimbi.

●I-Z-axis inikwe amandla kagesi, okuvumela ukugxila kwesithombe ngokuzenzakalela.

I-lever engaphambili kwe-illuminator yenza ukushintshana phakathi kwamasimu akhanyayo namnyama kube lula futhi inomsebenzi wokuxhumanisa isihlungi esingathathi hlangothi. Lokhu kuvimbela amehlo omsebenzisi ukuthi akhuthazwe ukukhanya okunamandla lapho eshintsha esuka emasimuni amnyama aye emasimu akhanyayo, okuthuthukisa induduzo yomsebenzisi.

I-converter enezimbobo eziningi ivumela ukubonwa okunengqondo nokuqhubekayo ekukhulisweni okuphansi, okuphakathi, kanye nokuphezulu kwesampula efanayo ezindaweni ezahlukene zokubuka.

| Uhlelo lokubona | Uhlelo lwe-optical olulungisiwe ngokungapheli |

| Ipayipi lokubuka | Ukuthambekela okungu-30°, ithubhu lokubuka elinobubanzi obungapheli elinobubanzi obuthathu, ukulungiswa kwebanga phakathi kwabantwana: 50mm~76mm, isilinganiso sokuhlukana kwemisebe enamazinga amabili, i-binocular:trino = 100:0 noma 0:100 |

| i-eyepiece | I-eyepoint ephezulu, i-eyepiece ebanzi yohlelo lokubukwa kwe-PL10X / 25mm, i-diopter elungisekayo. |

| Amasimu akhanyayo namnyamaIlensi eqondile eyinkimbinkimbi | I-LMPLFL 5X /0.15 BD DIC WD13.5mmI-LMPLFL10X/0.30 BD DIC WD9.0mmI-LMPLFL20X/0.5 BD DIC WD2.5mmI-LMPLFL50X/0.80 BD WD1.0mmI-LMPLFL100X / 0.90 BD WD 1.0mm |

| isiguquli | Isiguquli esinezimbobo ezi-6 samasimu akhanyayo namnyama, esinesikhala se-DIC |

| uhlaka | Ikhamera inohlaka lokubonisa kanye nendlela yokugxila ephansi ye-coaxial coarse kanye ne-fine focus. Ukuhamba kokulungisa okuqinile kungu-25mm, kanti ukunemba kokulungisa okuqinile kungu-0.001mm. Ifaka idivayisi yokucindezela yokulungisa okulwa nokushelela kanye neswishi engahleliwe yomkhawulo ophezulu. |

| Uhlelo lokukhanyisa | Isibani esikhanyayo nesikhala esimnyama esine-diaphragm yokuvula eguquguqukayo, i-diaphragm yensimu, kanye ne-maphakathi elungisekayo; nedivayisi yokushintsha ukukhanya kwensimu ekhanyayo nesikhala esimnyama; nesikhala sokuhlunga umbala kanye nesikhala se-polarizer/analyzer. |

| igumbi lesibani | Igumbi lesibani se-halogen esingu-12V esingu-100W, elifanele kokubili ukudluliselwa kanye nokuboniswa, liyatholakala ukuze li-odwe kusengaphambili. |

| I-axis ka-Z | Ukugxila Okuzenzakalelayo |

| Ipulatifomu kagesi | Ukuhamba kwepulatifomu: Isiqondiso esivundlile * Isiqondiso esivundlile = 80 * 60 (iyunithi: mm)I-screw lead: 2000μmUkunemba kokuphindaphinda kwe-XY: ngaphakathi kwe-± 2 μmUkuphindaphindwa kwe-Z-axis: ngaphakathi kwe-± 1 μmIsixazululo ezindaweni ezingu-16: 0.625μm ngesinyathelo ngasinye I-engeli yesinyathelo se-Stepper motor: 1.8° Isilinganiso samanje sokusebenza: 1.0A ngomshafti ngamunye (sisebenza ngama-24V) Umthwalo omkhulu: ≥5kg Isikhala esiphezulu sokuhamba nokubuya: 2 micrometer Ukuphakama okuphezulu kwesampula kungu-25mm (okunye ukuphakama kungenziwa ngezifiso). |

| Ibhokisi lokulawula idrayivu | Isebenzisa i-RS232 serial port ejwayelekile ukuxhumana ne-PC (isilinganiso se-baud esingu-115200).Ukulawulwa kwe-serial port kuvumela ukusetha isivinini semoto, ibanga, kanye nesiqondiso sokunyakaza. |

| Ezinye izinamathiselo | Isifaki se-Polarizer, isifaki se-analyzer esijikelezayo esingu-360°, kanye nesihlungi sokuphazamiseka esisethwe ukuze kuboniswe. |

| Uhlelo Lokuhlaziya | Isofthiwe yokuhlaziya i-metallographic yangempela ye-FMIA 2025 kanye nesofthiwe ye-porosity |

| idivayisi yekhamera | Ama-megapixel angu-5, ama-fps angu-36 |

| Isixhumi esibonakalayo selensi ye-adaptha esingu-0.5X, i-micrometer | |

| Amakhompyutha okulawula ezimboni | I-Intel i5 processor , 64GB RAM , 1TB SSD , 27-inch 4K monitor |

Isofthiwe yethu yokuhlaziya izithombe ze-metallographic iyisistimu entsha sha eyakhiwe yinkampani yethu ngokusekelwe ezidingweni zokuhlola ze-metallographic zamabhizinisi okusakaza, amabhizinisi ezingxenye zezimoto, amabhizinisi okwelapha ukushisa, imboni yensimbi ethwala izinsimbi, imboni yesistimu yamandla, imboni yezingxenye zesitimela, kanye nezinkampani ezahlukene zokuhlola ezihlobene. Ukuze sithuthukise izinga lokufaneleka komkhiqizo futhi sisize ekuthuthukiseni izinga lokuhlola lama-laboratory ahlukahlukene, siqoqe izidingo nemibono yochwepheshe nothisha abavela ezimbonini ezahlukene.

Isofthiwe yokuhlaziya izithombe ze-metallographic ihlelwe kabusha futhi yathuthukiswa ngokuphelele. Uhlelo luhlanganisa inani elikhulu lezindinganiso zokuhlola ze-metallographic zasekhaya nezamazwe ngamazwe, luhlanganisa ukuhlaziywa kwenani kanye nokwekhwalithi, futhi lunezela ukuhlanganiswa kokujula kwensimu kanye nemisebenzi yokuthunga yensimu yokubuka yesithombe. I-interface ilula futhi ingaqhubeka nokuthwebula izithombe zensimu yokubuka eminingi ukuze kuhlelwe futhi kuhlaziywe isithombe esiphakathi. Ukusebenza kulula kakhulu, kususa izinyathelo ezahlukahlukene ezinzima zesofthiwe yangaphambilini, okwenza ukuhlolwa kusheshe futhi kuphumelele kakhudlwana.

Sithuthukise uhlelo olusha sha lwamathuluzi okuhlaziya i-metallographic "oluchwepheshile, olunembile, nolusebenzayo" ukuze kube lula ukuhlaziya i-metallographic.

Umtapo wolwazi kazwelonke wesistimu yesofthiwe uqukethe amakhulu ezigaba, ngokuyisisekelo uhlanganisa amazinga e-metallographic asetshenziswa kakhulu futhi uhlangabezana nezidingo zokuhlaziywa kwe-metallographic kanye nokuhlolwa kwezinhlangano eziningi. Izigaba ezifanele zicacisiwe futhi zivulwa ngokwezidingo zezimboni ezahlukene ukuze kuhlangatshezwane nezidingo zokuhlolwa kwemboni. Wonke amamojula atholakala mahhala impilo yonke, futhi amazinga athuthukiswa mahhala impilo yonke.

Njengoba inani elikhulayo lezinto ezintsha kanye namamaki angenisiwe, izinto kanye nezindinganiso zokuhlola ezingakafakwa kusofthiwe zingenziwa ngezifiso futhi zifakwe ngokwehlukana.

Izinzuzo nemisebenziyesofthiwe yokuhlaziya i-metallographic:

- Ukuthwebula nokuthola izithombe zevidiyo eziningi: Ukuthwebula amaqoqo, ukuqanjwa kwamaqoqo, ukonga amaqoqo, ukuphrinta amaqoqo ngokukhulisa okuhleliwe kanye neminye imisebenzi yokucubungula amaqoqo amaningi kwenza inqubo yokuhlola isampula yamaqoqo ibe lula futhi isebenze kahle.

- Okuthuthukisiweizilungiselelo zekhamera:Isikhathi sokudalulwa, inzuzo, ubukhali, ukugcwala, i-gamma, ukuqhathanisa, ukukhanya, ibhalansi emhlophe, ibhalansi emnyama, kanye nezinye izilungiselelo zomsebenzi.

- Ukuchofoza okukodwaukulinganisa zonke izinhloso:Umsebenzi wokulinganisa uthuthukisiwe ngokuphelele, okukuvumela ukuthi uqedele ukulinganisa wonke amapharamitha aqondile ngokuchofoza okukodwa. Uma kuqhathaniswa nendlela yokuqala yokulinganisa, indlela entsha yokulinganisa ilula kakhulu futhi ishesha ukuyisebenzisa.

- Imisebenzi yokucubungula isithombe:ukuhlukaniswa kombala, ukuguqulwa kwe-grayscale, ukuvala, ukuhlukanisa izithombe, ukuthuthukiswa kwesithombe, ukuguqulwa kwesigaba, ukulola, ukususwa kokuklwebheka kanye nokungcola, i-histogram yesithombe, njll.

- Umphumela wokukala isithombe:Izici zifaka phakathi ukuphrinta kokukala izithombe eziningi, amagama ezithombe ezenziwe ngokwezifiso, izilungiselelo zamapharamitha esikali, ukuthumela ku-PDF/Word/Excel, kanye nokubuka kuqala kokuphrinta.

Ukulinganiswa kwesithombe nokugcinwa kwengobo yomlando:Amathuluzi ahlukahlukene okulinganisa ayatholakala (kufaka phakathi ibanga, i-engeli, i-engeli ephakathi kwemigqa emibili, unxande, ibanga eliqondile, i-ellipse, i-polygon, ibanga eliqondile, i-arc enamaphuzu amathathu, indilinga enamaphuzu amathathu, njll.), okuvumela ukudweba imicibisholo, ukulebula umbhalo, kanye nokwengeza...Izinketho eziningi ziyatholakala zemigqa esekelayo, ububanzi bomugqa, kanye namayunithi obude; umbala wefonti yedatha yokulinganisa, usayizi, kanye nesitayela sefonti nakho kuyatholakala; idatha yokuhlola ingafingqwa futhi ithunyelwe ku-Excel.

Umsebenzi wokuhlaziya inhlangano:Umtapo wesofthiwe uqukethe amazinga ahlukahlukene okuhlola, okuhlanganisa i-GB/ASTM/ISO/DIN/QC/JB/DL/TB/SS kanye nezinye izindinganiso zokuhlaziya izinhlangano. Izindinganiso kulabhulali yesofthiwe zingathuthukiswa mahhala, kanti isofthiwe inezici zokuhlaziya ezizenzakalelayo neziqhathanisayo. Inezici ezintathu zokulinganisa i-metallographic: eyinhloko, yesibili, kanye neyokusiza. Kulula, kulula, futhi kuyashesha ukuyisebenzisa, futhi inikeza izilinganiso ezinembile nezithembekile.

Izici zokwenza ngokwezifiso ezithuthukisiwe:Ukulawulwa kwesiteji okwenziwe nge-microscope okwenziwe ngokwezifiso, ukuhlanganiswa kwesithombe, imephu yokukhanya kwe-3D, isizindalwazi sesithombe, njll.

Amathempulethi emibiko ahlukahlukene:Ikhiqiza ngokuzenzakalelayo imibiko yokuhlaziywa kwe-metallographic enemifanekiso ecebile, enezinketho zezitayela zombiko we-module eyodwa noma we-module eziningi. Amathempulethi ombiko angashintshwa ukuze afake ama-logo enkampani, amagama enkampani, izinqubo zokuhlola, kanye nolunye ulwazi. Amathempulethi ombiko enziwe ngokwezifiso nawo ayatholakala ukuze ahlangabezane nezidingo zakho ezithile.

Umsebenzi wokuhlaziya izicubu osebenzisa i-AI:Imojuli yokuhlaziya izicubu ze-AI engenziwa ngokwezifiso isebenzisa ubuhlakani bokwenziwa ukuqedela yonke inqubo yokuhlaziya nokuthola isakhiwo esincane, ihlonza futhi ihlaziye ngokuzenzakalelayo isakhiwo esincane sezinto. Inqubo yokusebenza ilula, inciphisa amandla abasebenzi. Thuthukisa ukusebenza kahle kokuhlolwa kwezinto.

Umtapo Wolwazi Kazwelonke Wokudweba Okujwayelekile:Iqukethe amakhulu emidwebo ejwayelekile kazwelonke ukuze amakhasimende ayifunde futhi ayibhekisele kuyo.

Imodyuli Yokufundisa ye-Metallography:Kufaka phakathi imodyuli yokufundisa ye-metallography ukuze amakhasimende ayifunde futhi ayibhekisele kuyo.

Umsebenzi Wokukhulisa Insimu Wokujula Kwe-EDF:Kumasampula angalingani futhi angenakuqondaniswa ekugxilweni, isofthiwe inikeza ukujula okuguquguqukayo kwe-EDF komsebenzi wokudubula ensimini. Ngokulungisa isondo lesandla eligxile ku-Z-axis microscope le-Z-axis micro-adjustment, imininingwane ecacile kusampula izongezwa njalo efasiteleni lokubonisa le-EDF eliguquguqukayo ukuze kubuyekezwe ngokuguquguqukayo. Isofthiwe iqopha ngokuzenzakalelayo izithombe ezicacile ekujuleni okuhlukene kwensimu bese izihlanganisa zibe isithombe esicacile.

Umsebenzi wokuthunga isithombe:Kumakhasimende adinga ukuhlola insimu enkulu yokubuka, isofthiwe inikeza umsebenzi wokuthunga isithombe. Abasebenzisi bangahambisa ipulatifomu ye-XY ye-microscope ukuze bafinyelele ukuskena okugcwele kwezithombe kanye nokuhlanganiswa kwezithombe okusebenzayo kakhulu ukuqinisekisa ukuxhumana okungenamthungo kwezinkambu eziningi zokubuka. Lokhu kuhlangabezana nesidingo sekhasimende sokuthwebula izithombe zezinkambu ezinkulu zokubuka zesampula futhi kuxazulula ihlazo lokungakwazi ukuthatha izithombe ngenxa yokuntuleka kwensimu yokubuka ye-microscope eyanele.

Isekela izindlela zokuskena ezenziwe ngokwezifiso, ivumelana namasampula angajwayelekile, futhi ithuthukisa izinga lempumelelo lokuhlanganisa izindawo eziyinkimbinkimbi.

I-Z-axis inikwe amandla kagesi, okuvumela ukugxila kwesithombe ngokuzenzakalela.

| I-GB/T 10561-2023 Ukunqunywa Kokuqukethwe Okungenayo Insimbi Ensimbini | GB/T 34474.1-2017 Ukuhlolwa kwesakhiwo esinamabhande ensimbini |

| Ukuhlolwa kwe-GB/T 7216-2023 Metallographic kwe-Gray Cast Iron | Izinga Lokulinganisa I-DL/T 773-2016 Spheroidization Lensimbi engu-12Cr1MoV Esetshenziswa Ezitshalweni Zamandla Ezishisayo |

| GB / T 26656 - 2023 Ukuhlolwa kwe-Metallographic ye-Vermicular Graphite Cast Iron | Isilinganiso Sokuguga Se-DL / T 1422 - 2015 18Cr-8Ni Series Austenitic Stainless Steel Boiler Tube Microstructure Standard |

| Indlela Yokuhlola ye-GB/T 13299-2022 Yesakhiwo Esincane Sensimbi | I-GB /T 3489-2015 Ama-alloy aqinile - Ukunqunywa kwe-Metallographic kwe-porosity kanye ne-carbon engahlanganisiwe |

| Ukuhlolwa kwe-GB/T 9441-2021 Metallographic kwe-Ductile Iron | I-JB/T 1255-2014 Izimo Zobuchwepheshe Zokwelashwa Kokushisa Kwezingxenye Zensimbi Ezithwala I-Chromium Enekhabhoni Ephakeme Zama-Rolling Bearings |

| Ukuhlolwa kwe-GB/T 38720-2020 Metallographic kweNsimbi Ehlanganisiwe Yekhabhoni Ephakathi kanye neNsimbi Ehlanganisiwe Yekhabhoni Ephakathi | I-GB / T 1299 - Ithuluzi kanye neNsimbi ka-2014 |

| Indlela ye-GB/T 224-2019 Yokunquma Ukujula Kwesendlalelo Esikhishwe Ikhabhoni Ensimbini | GB / T 25744 - 2010 Ukuhlolwa kwe-Metallographic kwezingxenye zensimbi ezifakwe i-Carburised, ezicinyiwe, nezithambile |

| Ukuhlolwa kwe-TB/T 2942.2-2018 ZG230-450 Metallographic yensimbi ehlanganisiwe | Ukunqunywa kwe-GB/T13305-2008 Metallographic kokuqukethwe kwendawo yesigaba se-α ensimbi engagqwali |

| Ukuhlaziywa kwe-JB/T 5108-2018 Metallographic kwe-Cast Brass | JB/T 9204-2008 Ukuhlolwa kwe-Metallographic kwezingxenye zensimbi eziqinisiwe ze-Induction |

| Indlela ye-GB /T 6394-2017 Yokunquma Usayizi Ophakathi Wokusanhlamvu Kwezinsimbi | I-GB/T 13320-2007 Izinto zokubopha insimbi, imidwebo yokulinganisa isakhiwo se-metallographic kanye nezindlela zokuhlola |

| I-JB/T7946.1-2017 Metallography yama-Cast Aluminium Alloys | Izinga Lokulinganisa Insimbi Enezingqimba ze-DL/T 999-2006 Zezitshalo Zamandla |

| JB/T7946.2-2017 Ukushisa Okudlulele Kwe-Cast Aluminium-Silicon Alloys | Iziqondiso Zobuchwepheshe ze-DL/T 439-2006 Zezibambo Zokushisa Okuphezulu Ezitshalweni Zamandla Okushisa |

| Imbobo Yephinikhodi Ye-JB/T7946.3-2017 Ye-Cast Aluminium Alloy | Izinga le-DL/T 786-2001 Lokuhlola Nokulinganisa I-Graphitization Yensimbi Yekhabhoni |

| I-JB/T 7946.4-2017 Metallography yama-Cast Aluminium Alloys | I-B/T 1979-2001 Umdwebo wokulinganisa amaphutha esakhiwo esincane sensimbi esakhiwe |

| GB / T 34891 - 2017 Rolling Bearings_Izimo Zobuchwepheshe Zokwelashwa Kokushisa Kwezingxenye Zensimbi Ezithwala I-Chromium Enekhabhoni Ephakeme | I-DL/T 674-1999 Izinga Elijwayelekile Le-Pearlite Spheroidization Isilinganiso Sensimbi Engu-20 Yezitshalo Zamandla Okushisa |

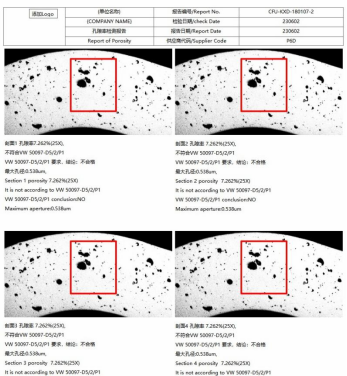

Uhlelo lokuhlaziya izithombe ze-porosity lwe-FKX2025 lusebenzisa izithombe ezincane ukuthola i-porosity yezingxenye zezimoto. Luhlelo lokulinganisa i-porosity lwe-aluminium ehlanganisiwe esetshenziswa embonini yezimoto, oluhambisana nezindinganiso ze-VW50097 ne-PV6097 zeVolkswagen. Imiphumela yokulinganisa inembile futhi ithembekile. Isetshenziselwa ikakhulukazi ukuhlaziya i-porosity yokwakheka kwe-aluminium alloys kanye ne-cast iron castings, futhi ifaneleka futhi ekuhlaziyweni kwe-porosity kanye nokuhlaziywa kwe-metallographic kwezinye izinto.

Isofthiwe yokuhlaziya isithombe se-porosity ingasetshenziswa ngesiteji sikagesi ukuze kufezwe ukuskena okuzenzakalelayo, ukugxila okuzenzakalelayo, ukuthunga izithombe okuzenzakalelayo, ukulinganisa i-porosity okuzenzakalelayo, izibalo zedatha, kanye nokukhishwa kwemibiko.

Umsebenzi wokuthunga isithombe:Setha amapharamitha okuthunga kanye nohlobo lwesithombe, chofoza okuthi "Auto Stitch," bese ukuthunga isithombe kuzoqedwa ngokuzenzakalelayo.

Izilungiselelo zepharamitha yokusesha:Ngokubeka indawo encane, indawo ephezulu, kanye nomkhawulo, ukusesha okugcwele kwemephu kungenziwa ukuthola wonke ama-pores ngaphakathi kwemingcele ebekiwe yemephu yonke.

Ukukhetha isithombe:Ihlinzeka ngamathuluzi okukhetha afana nonxande, i-polygon, indilinga, isikwele, kanye nonxantathu. Ngemva kokuthi ukukhetha sekuqediwe, isofthiwe yenza ngokuzenzakalelayo ukuhlaziywa kwe-porosity endaweni ekhethiwe.

Ukuhlaziywa kwe-pore:Ingahlaziya idatha efana nomngcele, indawo, i-axis enkulu, i-axis encane, ububanzi obulinganayo bendilinga, isilinganiso sesici, kanye nokuzungeza kwembobo ngayinye.

Ukulinganisa kwejometri:Amathuluzi ahlukahlukene okulinganisa angasetshenziswa ukuze alinganise ubukhulu

Izibalo zedatha kanye nokukhiqizwa kwemibiko:Ingahlaziya ngokwezibalo idatha yepharamitha enemininingwane yembobo ngayinye futhi ikhiqize izindlela ezimbili zokubika, i-VW50093 noma i-VW50097.