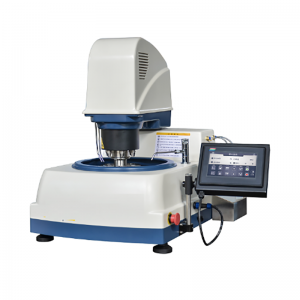

Umshini Wokupholisha Wesampula Yokugaya I-Metallographic Ozenzakalelayo we-MP-2000

Isiqondiso sokujikelezisa idiski yokugaya singakhethwa, idiski yokugaya ingashintshwa ngokushesha; Isihloli se-clamp samasampula amaningi kanye nokulayisha kwe-pneumatic single point kanye neminye imisebenzi. Umshini usebenzisa uhlelo lokulawula i-microprocessor oluthuthukisiwe, ukuze ijubane lediski yokugaya kanye nekhanda lokugaya lingalungiseki kalula, ingcindezi yesampula kanye nokusetha isikhathi kube lula futhi kube lula. Mane nje ufake ipuleti lokupholisha noma i-sandpaper kanye nendwangu ukuze uqedele inqubo yokugaya nokupholisha. Ngakho-ke, lo mshini ukhombisa ububanzi bezicelo. Unezici zokujikeleza okuzinzile, okuphephile nokuthembekile, umsindo ophansi, kanye nesisekelo se-aluminium esithungwayo sandisa ukuqina kokugaya nokupholisha.

Umshini ufakwe idivayisi yokupholisa amanzi, engapholisa isampula ngesikhathi sokugaya, ukuze kuvinjelwe isakhiwo esincane sesampula ukuba sonakale ngenxa yokushisa ngokweqile kanye nezinhlayiya ezihuzukayo ukuthi zingagezwa nganoma yisiphi isikhathi. Inegobolondo lensimbi yengilazi kanye nezingxenye ezijwayelekile zensimbi engagqwali, ezibukeka zinhle kakhulu futhi zinomusa, futhi zithuthukise ukugqwala, ukumelana nokugqwala kanye nokulula ukuzihlanza.

Ifanele ukulungiswa kwesampula okuzenzakalelayo enkambisweni yokugaya okungaqinile, ukugaya kahle, ukupholisha okungaqinile kanye nokupholisha kahle amasampula e-metallographic. Ingumshini ofanele wokwenza amasampula emalabhorethri amabhizinisi, izikhungo zocwaningo lwesayensi kanye namanyuvesi. Lo mshini kulula ukuwusebenzisa, uphephile futhi uthembekile, ungumshini ofanele wokwenza amasampula ezimbonini, izikhungo zocwaningo lwesayensi kanye namalabhorethri amakolishi namanyuvesi.

1. Umshini wokupholisha othomathikhi wohlobo lwesikrini sokuthinta sesizukulwane esisha. Uhlome ngamadiski amabili;

2. Ukulayisha iphuzu elilodwa lomoya, kungasekela ukugaya nokupholisha isampula yama-6pcs ngasikhathi sinye;

3. Indlela ejikelezayo yediski yokusebenza ingakhethwa ngokuthanda kwayo. Idiski yokugaya ingashintshwa ngokushesha.

4. Yamukela uhlelo lokulawula i-microprocessor oluthuthukisiwe, oluvumela isivinini esijikelezayo sediski yokugaya kanye nekhanda lokupholisha ukuthi lilungiswe.

5. Ukulungiselela isampula ingcindezi kanye nesikhathi kuqondile futhi kulula. Inqubo yokugaya nokupholisha ingafezwa ngokufaka esikhundleni sediski yokugaya noma iphepha lesihlabathi kanye nendwangu yokupholisha.

Isebenza ekugayeni okungaqinile, ekugayeni kahle, ekupholisheni okungaqinile kanye nasekupholisheni kokuqeda ukulungiselela amasampula. Inketho ekahle kakhulu yelebhu yamafektri, isayensi kanye nezikhungo zocwaningo kanye namanyuvesi.

Ububanzi bediski yokusebenza: 250mm (203mm, 300mm kungenziwa ngezifiso)

Isivinini esijikelezayo sediski yokusebenza: 50-1000rpm Isivinini esincane sokushintsha noma 200 r/min, 600 r/min, 800 r/min, 1000 r/min Isivinini esingaguquki samazinga amane (sisebenza ku-203mm no-250mm, 300mm kudingeka senziwe ngokwezifiso)

Ijubane lokujikeleza lekhanda lokupholisha: 5-100rpm

Ububanzi bokulayisha: 5-60N

Isikhathi sokulungiselela isampula: 0-9999S

Ububanzi besampula: φ30mm (φ22mm,φ45mm kungenziwa ngezifiso)

I-Voltage Yokusebenza: 220V/50Hz, isigaba esisodwa; 220V/60HZ, izigaba ezi-3.

Ubukhulu: 710mmX760mmX680mm

Injini: 1500w

I-GW/NW: 125KGS/96KGS

Ukucushwa Okujwayelekile:

| Izincazelo | Ubuningi | Ipayipi lamanzi lokungena | 1 isiqephu. |

| Umshini Wokugaya/Wokupholisha | Isethi e-1 | Ipayipi lamanzi eliphuma ngaphandle | 1 isiqephu. |

| Ukupholisha indwangu | 2 izingcezu. | Incwadi yemiyalelo | Isabelo esingu-1 |

| Iphepha elinolaka | 2 izingcezu. | Uhlu lokupakisha | Isabelo esingu-1 |

| Idiski Yokugaya Nokupholisha | 1 isiqephu. | Isitifiketi | Isabelo esingu-1 |

| Indandatho yokubopha | 1 isiqephu. | ||