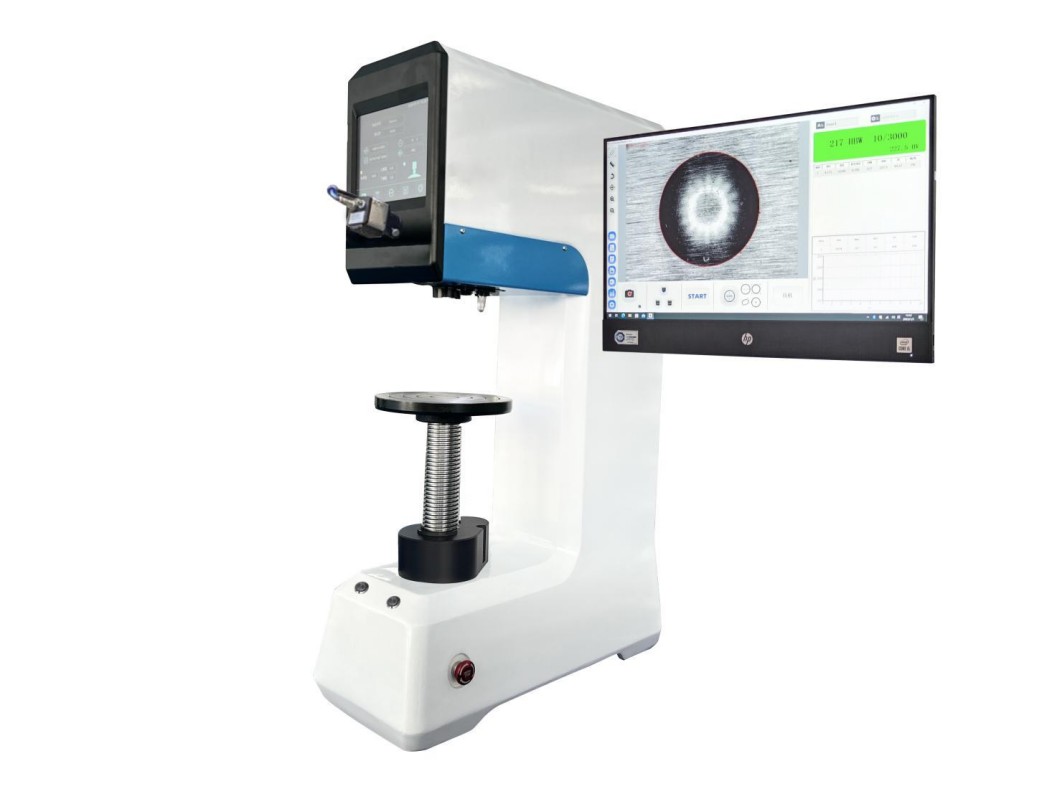

Ukuhlolwa kobulukhuni beBrinell kwasungulwa ngunjiniyela waseSweden uJohan August Brinell ngo-1900 futhi kwaqala ukusetshenziswa ukukala ubulukhuni bensimbi.

(1)HB10/3000

①Indlela yokuhlola kanye nesimiso: Ibhola lensimbi elinobubanzi obungu-10 mm licindezelwa ebusweni bezinto ezibonakalayo ngaphansi komthwalo ongu-3000 kg, bese ububanzi bokugoba bulinganiswa ukuze kubalwe inani lobunzima.

②Izinhlobo zezinto ezisebenzayo: Zifanele izinto zensimbi eziqinile njengensimbi ephonswe, insimbi eqinile, ama-alloy asindayo, njll.

③Izimo ezivamile zokusetshenziswa: Ukuhlolwa kwezinto zokwakha imishini esindayo nemishini. Ukuhlolwa kokuqina kwezinto ezinkulu ezibunjiwe kanye nezinto zokubumba. Ukulawulwa kwekhwalithi kwezobunjiniyela kanye nokukhiqiza.

④Izici nezinzuzo: Umthwalo omkhulu: Ifanele izinto ezijiyile neziqinile, ingamelana nengcindezi enkulu, futhi iqinisekise imiphumela yokulinganisa enembile. Ukuqina: I-indenter yebhola lensimbi inokuqina okuphezulu futhi ifanele ukusetshenziswa isikhathi eside nokuphindaphindiwe. Uhlu olubanzi lwezicelo: Iyakwazi ukuhlola izinhlobo ezahlukene zezinto zensimbi eziqinile.

⑤Amanothi noma imikhawulo: Usayizi wesampula: Kudingeka isampula enkulu ukuqinisekisa ukuthi ukugoba kukhulu ngokwanele futhi kunembile, futhi ubuso besampula kumele bube yisicaba futhi buhlanzeke. Izidingo zobuso: Ubuso budinga ukuba bushelelezi futhi bungabi nakungcola ukuqinisekisa ukunemba kokulinganisa. Ukugcinwa kwemishini: Imishini idinga ukulinganiswa nokugcinwa njalo ukuqinisekisa ukunemba nokuphindaphinda kokuhlolwa.

(2)HB5/750

①Indlela yokuhlola kanye nesimiso: Sebenzisa ibhola lensimbi elinobubanzi obungu-5 mm ukuze ucindezele ebusweni bezinto ezingaphansi komthwalo ongu-750 kg, bese ulinganisa ububanzi bokugoba ukuze ubale inani lobunzima.

②Izinhlobo zezinto ezisebenzayo: Zisebenza ezintweni zensimbi ezinobulukhuni obuphakathi, njengezinsimbi zethusi, izinsimbi ze-aluminium, kanye nensimbi enobulukhuni obuphakathi. ③ Izimo ezivamile zokusetshenziswa: Ukulawulwa kwekhwalithi yezinto zensimbi ezinobulukhuni obuphakathi. Ucwaningo lwezinto zokwakha kanye nokuthuthukiswa kwazo kanye nokuhlolwa kwelebhu. Ukuhlolwa kobulukhuni bezinto ngesikhathi sokukhiqiza nokucubungula. ④ Izici nezinzuzo: Umthwalo ophakathi: Zisebenza ezintweni ezinobulukhuni obuphakathi futhi zingalinganisa ngokunembile ubulukhuni bazo. Ukusetshenziswa okuguquguqukayo: Zisebenza ezintweni ezahlukahlukene zobulukhuni obuphakathi ezinokuzivumelanisa nezimo ezinamandla. Ukuphindaphinda okuphezulu: Kunikeza imiphumela yokulinganisa ezinzile nehambisanayo.

⑥Amanothi noma imikhawulo: Ukulungiswa kwesampula: Ubuso besampula budinga ukuba bucwenge futhi bube yisicaba ukuqinisekisa ukunemba kwemiphumela yokulinganisa. Imikhawulo yezinto zokwakha: Kwezinto zokwakha ezithambile kakhulu noma eziqinile kakhulu, kungadingeka kukhethwe ezinye izindlela zokuhlola ubulukhuni ezifanele. Ukugcinwa kwemishini: Imishini idinga ukulinganiswa nokugcinwa njalo ukuqinisekisa ukunemba nokuthembeka kokulinganisa.

(3)HB2.5/187.5

①Indlela yokuhlola kanye nesimiso: Sebenzisa ibhola lensimbi elinobubanzi obungu-2.5 mm ukuze ucindezele ebusweni bezinto ezingaphansi komthwalo ongu-187.5 kg, bese ulinganisa ububanzi bokugoba ukuze ubale inani lobunzima.

②Izinhlobo zezinto ezisebenzayo: Zisebenza ezintweni zensimbi ezithambile kanye nezinye izinhlobo ezithambile, njenge-aluminium, i-lead alloy, kanye nensimbi ethambile.

③Izimo ezivamile zokusetshenziswa: Ukulawulwa kwekhwalithi yezinto zensimbi ethambile. Ukuhlolwa kwezinto embonini ye-elekthronikhi nekagesi. Ukuhlolwa kokuqina kwezinto ezithambile ngesikhathi sokukhiqiza nokucubungula.

④Izici nezinzuzo: Umthwalo ophansi: Kusebenza ezintweni ezithambile ukuze kugwenywe ukubhoboka ngokweqile. Ukuphindaphinda okuphezulu: Kunikeza imiphumela yokulinganisa ezinzile nengaguquguquki. Uhlu olubanzi lwezicelo: Kuyakwazi ukuhlola izinhlobo ezahlukene zezinto zensimbi ezithambile.

⑤ Amanothi noma imikhawulo: Ukulungiswa kwesampula: Ubuso besampula budinga ukuba bucwenge futhi bube yisicaba ukuqinisekisa ukunemba kwemiphumela yokulinganisa. Imikhawulo yezinto zokwakha: Kuzinto zokwakha eziqinile kakhulu, kungadingeka ukukhetha ezinye izindlela zokuhlola ubulukhuni ezifanele. Ukugcinwa kwemishini: Imishini idinga ukulinganiswa nokugcinwa njalo ukuqinisekisa ukunemba nokuthembeka kokulinganisa.

Isikhathi sokuthunyelwe: Novemba-20-2024