Ikhodi yokuqina kwensimbi yi-H. Ngokwezindlela ezahlukene zokuhlola ubulukhuni, izethulo ezivamile zifaka phakathi i-Brinell (HB), i-Rockwell (HRC), i-Vickers (HV), i-Leeb (HL), ubulukhuni be-Shore (HS), njll., phakathi kwazo i-HB ne-HRC ezisetshenziswa kakhulu. I-HB inezinhlobo eziningi zezicelo, futhi i-HRC ifaneleka ezintweni ezinobulukhuni obuphezulu, njengokuqina kokwelashwa kokushisa. Umehluko uwukuthi i-indenter yesihloli sobulukhuni ihlukile. Isihloli sobulukhuni be-Brinell siyi-indenter yebhola, kanti isihloli sobulukhuni be-Rockwell siyi-indenter yedayimane.

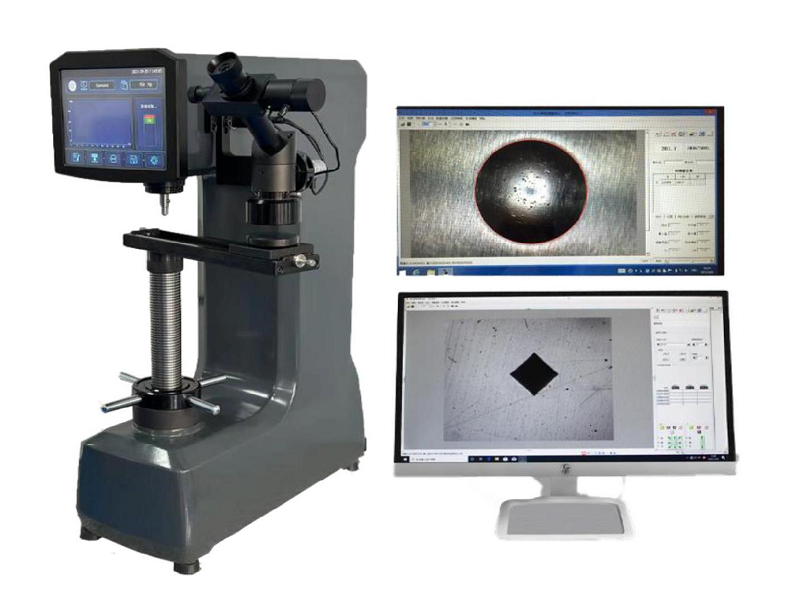

I-HV-ifanele ukuhlaziywa kwe-microscope. Ubulukhuni be-Vickers (HV) Cindezela ubuso bezinto ngomthwalo ongaphansi kuka-120kg kanye ne-indenter yekhoni yesikwele yedayimane ene-engeli ye-vertex engu-136°. Indawo engaphezulu yembobo yento ihlukaniswe ngenani lomthwalo, okuyinani lobulukhuni be-Vickers (HV). Ubulukhuni be-Vickers buvezwa njenge-HV (bheka i-GB/T4340-1999), futhi bulinganisa amasampula amancane kakhulu.

Isihloli sokuqina esiphathwayo se-HL silungele ukukalwa. Sisebenzisa ikhanda lebhola lokushaya ukuze sithinte ubuso bokuqina futhi sikhiqize ukugxuma. Ubulukhuni bubalwa ngesilinganiso sejubane lokubuyela emuva kwesibhakela ku-1mm ukusuka ebusweni besampula kuya esivinini sokushaya. Ifomula ithi: Ubulukhuni be-Leeb HL=1000×VB (isivinini sokubuyela emuva)/VA (isivinini somthelela).

Isihloli sokuqina kwe-Leeb esiphathekayo singaguqulwa sibe yi-Brinell (HB), Rockwell (HRC), Vickers (HV), Shore (HS) ngemva kokulinganisa i-Leeb (HL). Noma sebenzisa isimiso se-Leeb ukukala ngqo inani lokuqina nge-Brinell (HB), Rockwell (HRC), Vickers (HV), Leeb (HL), Shore (HS).

Ubulukhuni be-HB - Brinell:

Ukuqina kweBrinell (HB) kuvame ukusetshenziswa lapho izinto zithambile, njengezinsimbi ezingezona insimbi, insimbi ngaphambi kokwelashwa ngokushisa noma ngemva kokufakelwa. Ukuqina kweRockwell (HRC) kuvame ukusetshenziswa ezintweni ezinobunzima obuphezulu, njengokuqina ngemva kokwelashwa ngokushisa, njll.

Ubunzima beBrinell (HB) buwumthwalo wokuhlola wosayizi othile. Ibhola lensimbi eqinile noma ibhola le-carbide lobubanzi obuthile licindezelwa ebusweni bensimbi ukuze lihlolwe. Umthwalo wokuhlola ugcinwa isikhathi esithile, bese umthwalo ususwa ukuze kulinganiswe ububanzi bokugoba ebusweni obuzohlolwa. Inani lobunzima beBrinell yi-quotient etholakala ngokuhlukanisa umthwalo ngendawo yobuso obuyindilinga bokugoba. Ngokuvamile, ibhola lensimbi eqinile lobukhulu obuthile (ngokuvamile ububanzi obuyi-10mm) licindezelwa ebusweni bezinto ezibonakalayo ngomthwalo othile (ngokuvamile u-3000kg) futhi ligcinwe isikhathi esithile. Ngemva kokususwa komthwalo, isilinganiso somthwalo endaweni yokugoba yinani lobunzima beBrinell (HB), kanti iyunithi iyi-kilogram force/mm2 (N/mm2).

Ubulukhuni beRockwell bunquma inkomba yenani lobulukhuni ngokusekelwe ekujuleni kokuguquguquka kwepulasitiki kokugoba. 0.002 mm isetshenziswa njengeyunithi yobulukhuni. Uma i-HB>450 noma isampula incane kakhulu, isivivinyo sobulukhuni beBrinell asikwazi ukusetshenziswa futhi kusetshenziswa isilinganiso sobulukhuni beRockwell esikhundleni salokho. Isebenzisa ikhoni yedayimane ene-angle ye-vertex engu-120° noma ibhola lensimbi elinobubanzi obungu-1.59 noma 3.18mm ukucindezela ebusweni bento engaphansi kokuhlolwa ngaphansi komthwalo othile, futhi ubulukhuni bento bubalwa kusukela ekujuleni kokugoba. Ngokusho kobulukhuni bento ehlolwayo, buvezwa ngezikali ezintathu ezahlukene:

I-HRA: Ubulukhuni obutholakala ngokusebenzisa umthwalo ongu-60kg kanye ne-indenter yekhoni yedayimane, esetshenziselwa izinto ezinobulukhuni obuphezulu kakhulu (njenge-carbide eqinisiwe, njll.).

I-HRB: Ubulukhuni obutholakala ngokusebenzisa umthwalo ongu-100kg kanye nebhola lensimbi eqinile elinobubanzi obungu-1.58mm, elisetshenziselwa izinto ezinobulukhuni obuphansi (njengensimbi eqoshiwe, insimbi ephonswe, njll.).

I-HRC: Ubulukhuni obutholakala ngokusebenzisa umthwalo ongu-150kg kanye ne-indenter yekhoni yedayimane, esetshenziselwa izinto ezinobulukhuni obuphezulu kakhulu (njengensimbi eqinile, njll.).

Ngaphezu kwalokho:

1. I-HRC isho isikali sokuqina kwe-Rockwell C.

2. I-HRC ne-HB zisetshenziswa kabanzi ekukhiqizeni.

3. Ibanga elisebenzayo le-HRC HRC 20-67, elilingana ne-HB225-650,

Uma ubulukhuni buphakeme kunalolu hlu, sebenzisa i-Rockwell hardness A scale HRA,

Uma ubulukhuni buphansi kunalolu hlu, sebenzisa isikali sobulukhuni se-Rockwell B HRB,

Umkhawulo ophezulu wobulukhuni beBrinell yi-HB650, okungenakuba ngaphezulu kwaleli nani.

4. I-indenter yesikali se-C sokuhlola ubulukhuni be-Rockwell iyi-cone yedayimane ene-angle ye-vertex engama-degrees angu-120. Umthwalo wokuhlola unenani elithile. Izinga lesiShayina lingu-150 kgf. I-indenter yesikali se-Brinell sokuhlola ubulukhuni yibhola lensimbi eqinile (i-HBS) noma ibhola le-carbide (i-HBW). Umthwalo wokuhlola uyahlukahluka ngobubanzi bebhola, kusukela ku-3000 kuya ku-31.25 kgf.

5. Ukufakwa kobulukhuni eRockwell kuncane kakhulu, futhi inani elilinganisiwe litholakala endaweni. Kudingeka ukukala amaphuzu amaningana ukuthola inani elimaphakathi. Lifanele imikhiqizo eqediwe kanye nezingcezu ezincane futhi lihlukaniswa njengokuhlolwa okungabhubhisi. Ukufakwa kobulukhuni eBrinell kukhulu, inani elilinganisiwe linembile, alifanele imikhiqizo eqediwe kanye nezingcezu ezincane, futhi ngokuvamile alihlukaniswa njengokuhlolwa okungabhubhisi.

6. Inani lobulukhuni bobulukhuni beRockwell liyinombolo engashiwongo ngegama engenamayunithi. (Ngakho-ke, akulungile ukubiza ubulukhuni beRockwell ngezinga elithile.) Inani lobulukhuni beBrinell bunamayunithi futhi linobuhlobo obuthile obulinganiselwe namandla okudonsa.

7. Ubulukhuni beRockwell buboniswa ngqo ku-dial noma buboniswa ngedijithali. Kulula ukuyisebenzisa, kuyashesha futhi kuyashesha, futhi kufanelekile ekukhiqizweni ngobuningi. Ubulukhuni beBrinell budinga imakroskopu ukuze kulinganiswe ububanzi bokugoba, bese kubhekwe etafuleni noma kubalwe, okuyinto enzima kakhulu ukuyisebenzisa.

8. Ngaphansi kwezimo ezithile, i-HB ne-HRC zingashintshwa ngokubheka etafuleni. Ifomula yokubala ngengqondo ingaqoshwa cishe kanje: 1HRC≈1/10HB.

Ukuhlolwa kobulukhuni kuyindlela yokuhlola elula nelula ekuhlolweni kwempahla yomshini. Ukuze kusetshenziswe ukuhlolwa kobulukhuni ukuze kuthathelwe indawo ukuhlolwa okuthile kwempahla yomshini, kudingeka ubudlelwano bokuguqulwa obunembile phakathi kobulukhuni namandla ekukhiqizweni.

Umkhuba ufakazele ukuthi kukhona ubudlelwano obuhambisanayo obufanayo phakathi kwamanani ahlukahlukene obulukhuni bezinto zensimbi naphakathi kwenani lobulukhuni kanye nenani lamandla. Ngenxa yokuthi inani lobulukhuni linqunywa ukumelana kokuqala kokuguquguquka kwepulasitiki kanye nokumelana okuqhubekayo kokuguquguquka kwepulasitiki, lapho amandla ezinto zokwakha ephakeme, ukumelana kokuguquguquka kwepulasitiki kuphakeme, kanye nenani lobulukhuni liphakeme.

Isikhathi sokuthunyelwe: Agasti-16-2024