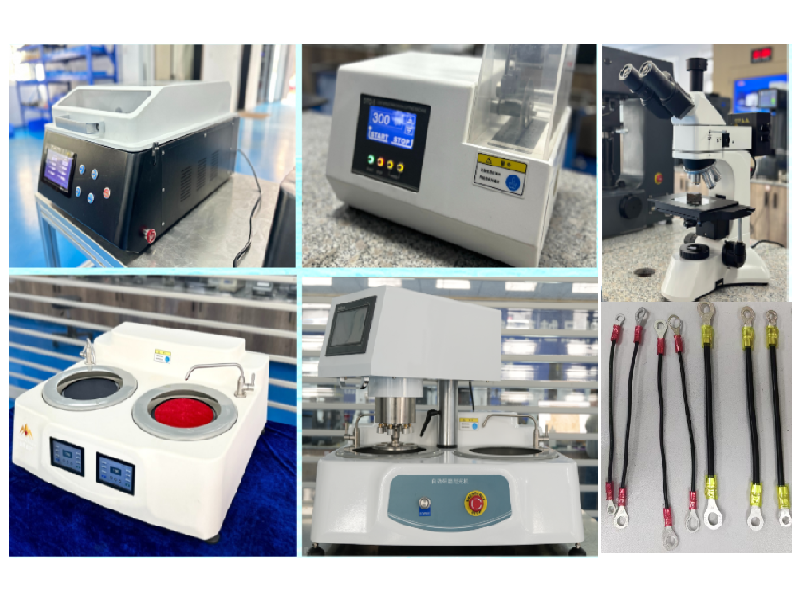

Indinganiso idinga ukuthi isimo sokugoqa setheminali yokuxhuma siyafaneleka yini. Ukugoqa kwentambo yokugoqa yetheminali kubhekisela esilinganisweni sendawo engaxhunywanga ye.ingxenye exhumanisayo esigungwini sokugoqa endaweni iyonke, okuyipharamitha ebalulekile ethinta ukuphepha nokuthembeka kwesigungwini sokugoqa. Ukugoqa okuphezulu kakhulu kuzoholela ekuthinteni okubi, kwandise ukumelana nokushisa, ngaleyo ndlela kuthinte ukuzinza nokuphepha kokuxhumeka kukagesi. Ngakho-ke, imishini yokuhlaziya i-metallographic yobungcweti iyadingeka ukuze kutholakale futhi kuhlaziywe ukugoqa okuphezulu. Ukusika isampula ye-Metallographic, umshini wokugaya nokupholisha isampula ye-metallographic, kanye ne-metallographic microscope kuyadingeka ukuze kuhlolwe futhi kulungiswe isigungwini, bese kuthi isithombe se-graphic sihlaziywe yisofthiwe ye-metallographic microscope yokuhlola isigaba se-terminal.

Inqubo yokulungiselela isampula: Isampula okufanele ihlolwe (izimbambo zokuqinisa ze-terminal kufanele zigwenywe) iyasikwa futhi ithathwe isampula ngomshini wokusika isampula we-metallographic - kunconywa ukusebenzisa umshini wokusika onembile wokusika, bese ingxenye yokusebenza etholakele ifakwe kusampula enamapulatifomu amabili kusetshenziswa umshini wokufaka i-metallographic, bese kuthi indawo yokuhlola efakwe i-inlay idinga ukugaywa futhi ipholishwe ibe yisibuko nge-grinder ye-metallographic bese ipholishwa, bese igqwala ngamakhemikhali bese ifakwa ngaphansi kwe-microscope ye-metallographic ukuze ihlolwe futhi ihlaziywe.

Isikhathi sokuthunyelwe: Mashi-28-2025