Emikhiqizweni yezimboni, insimbi yegiya isetshenziswa kabanzi ezinhlelweni zokudlulisa amandla emishini eyahlukahlukene yemishini ngenxa yamandla ayo aphezulu, ukumelana nokuguguleka kanye nokumelana nokukhathala. Ikhwalithi yayo ithinta ngqo ikhwalithi nokuphila kwemishini. Ngakho-ke, ukulawulwa kwekhwalithi yensimbi yegiya kubaluleke kakhulu. Lapho ukhetha, amandla ayo, ukuqina kanye nokumelana nokuguguleka kufanele kucatshangelwe. Ngaphambi kokucubungula insimbi yegiya, sidinga ukuhlaziya isakhiwo se-metallographic, ubulukhuni, ukwakheka kwamakhemikhali, njll. kwezinto. Isakhiwo se-metallographic kanye nobunzima bensimbi yegiya kuyizinkomba ezibalulekile zokuhlola izakhiwo zayo zemishini, imiphumela yokwelashwa kokushisa kanye nokuphila kwenkonzo. Ukuhlaziywa kwe-metallographic kanye nokuhlolwa kobulukhuni bensimbi yegiya kumele kulandele ngokuqinile inqubo ejwayelekile, futhi kwakheke uhlelo lokuhlola olusekelwe ezicini zezinto kanye nezimo zokusebenza:

Okokuqala, ukuhlaziywa kwe-metallographic. Isakhiwo se-metallographic sensimbi yegiya sinethonya elikhulu ekusebenzeni kwayo, njengokujula kwesendlalelo esifakwe i-carburized, usayizi wezinhlamvu, ukusatshalaliswa kwe-carbide, njll. Kuyadingeka ukunquma izinyathelo zokuhlaziya, njengokuthatha amasampula, ukulungiselela isampula, ukugqwala, bese ubheka isakhiwo. Kungadingeka futhi ukusho izinhlobo zezicubu ezivamile, njenge-martensite, i-bainite, i-pearlite, nokuthi ungahlola kanjani ukuthi lezi zicubu ziyahlangabezana yini nezindinganiso.

Bese kufika isivivinyo sobulukhuni. Ubulukhuni bensimbi yegiya buhlobene ngqo nokumelana nokuguguleka kanye namandla. Izindlela ezivamile zokuhlola ubulukhuni zifaka phakathi ubulukhuni beRockwell, ubulukhuni beBrinell, ubulukhuni beVickers, kanye nobunzima beRockwell obungaphezulu kwezingqimba ezifakwe i-carburing. Kuyadingeka ukuchaza izimo ezifanele zezindlela ezahlukene zokuhlola, njengeVickers noma iRockwell engaphezulu kwezingqimba ezifakwe i-carburing, kanye neBrinell noma iRockwell ebulukhunini obuphelele. Ngesikhathi esifanayo, amazinga okuhlola, njenge-ASTM noma i-GB, kanye nezinyathelo zokuphepha ngesikhathi sokuhlolwa, njengokukhethwa kwamaphuzu okuhlola, ukwelashwa kwendawo, njll., kufanele kukhulunywe ngakho.

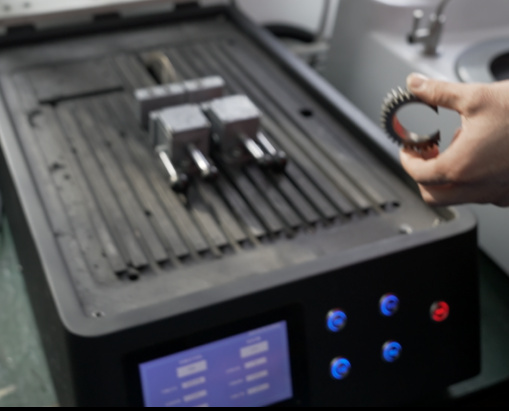

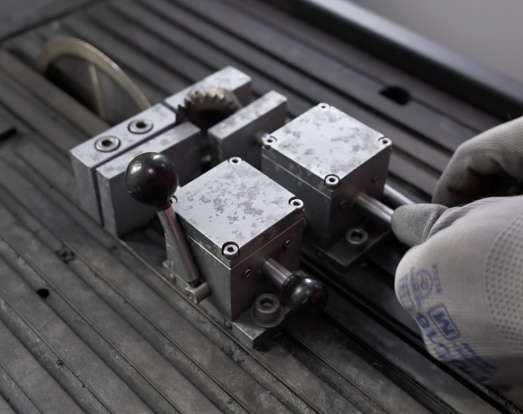

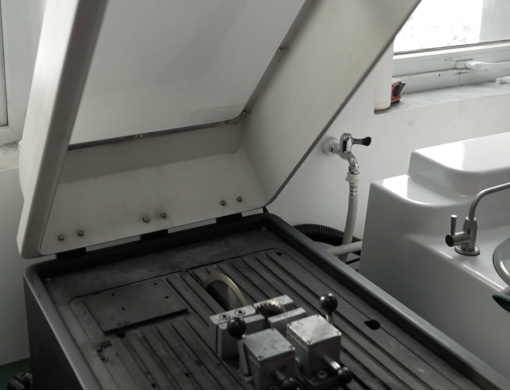

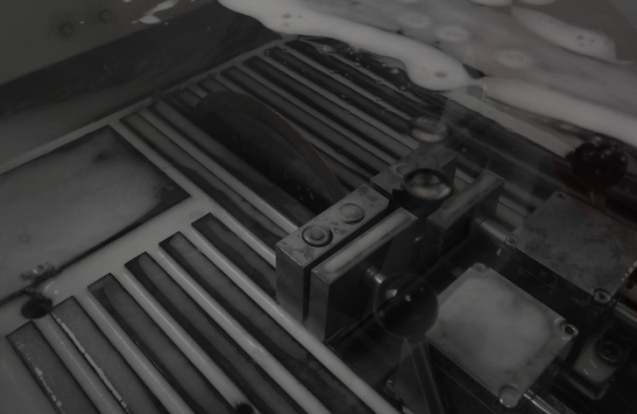

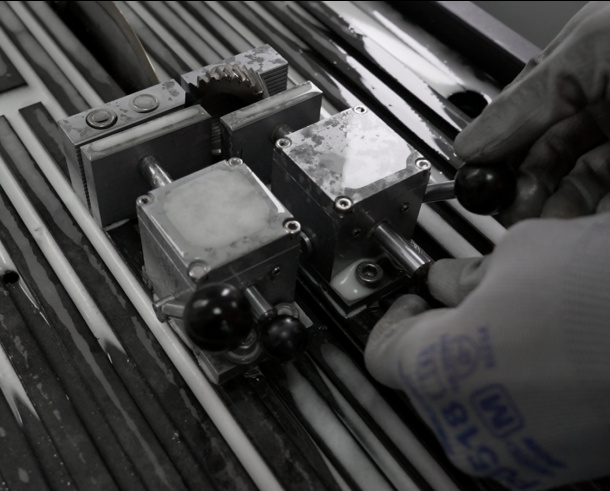

Ngaphambi kokuhlaziya, sidinga kuqala ukusika nokusampula insimbi yegiya. Ngezansi sisebenzisa umshini wokusika isampula ye-metallographic enembile njengesibonelo ukukhombisa inqubo yokusika isampula.

1. Khipha umsebenzi bese uwubopha nge-clamp esheshayo.

2. Ngemva kokubopha i-workpiece, gqoka isembozo esivikelayo.

3. Setha amapharamitha okusika esikrinini bese uqala uhlelo lokusika

4. Vula isembozo esingaphezulu bese ukhipha isampula esinqunyiwe ukuze uqedele inqubo yokusika isampula.

Amasampula asikiwe angasetshenziswa ezinqubweni ezilandelayo zokulungiselela amasampula njengokufaka, ukugaya, nokupholisha, ngemva kwalokho ukuhlolwa kobulukhuni begiya noma ukuhlaziywa kwe-metallographic kungenziwa.

Isikhathi sokuthunyelwe: Ephreli-02-2025