1) Ingabe isihloli sokuqina kweRockwell singasetshenziswa ukuhlola ubulukhuni bodonga lwepayipi lensimbi?

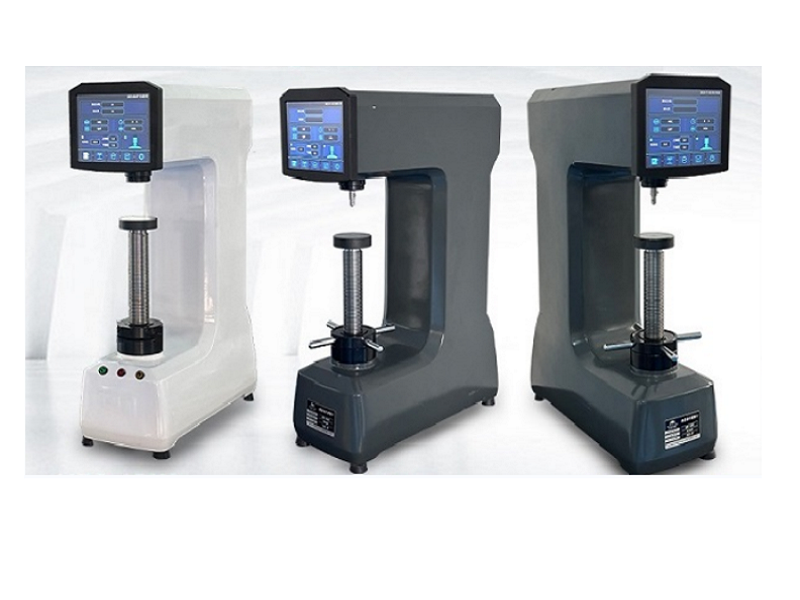

Izinto zokuhlola ziyipayipi lensimbi le-SA-213M T22 elinobubanzi bangaphandle obungu-16mm kanye nobukhulu bodonga obungu-1.65mm. Imiphumela yokuhlolwa kokuhlolwa kokuqina kwe-Rockwell imi kanje: Ngemva kokususa isikali se-oxide kanye nesendlalelo sokususa i-carburization ebusweni besampula nge-grinder, isampula ibekwa ebhentshini lokusebenzela elinomfanekiso ongu-V, kanti isihloli sokuqina kwe-Rockwell sedijithali se-HRS-150S sisetshenziselwa ukuhlola ngqo ubunzima be-Rockwell ebusweni bayo bangaphandle ngomthwalo ongu-980.7N. Ngemva kokuhlolwa, kungabonakala ukuthi udonga lwepayipi lensimbi lunokuguquguquka okuncane, futhi umphumela uba ukuthi inani lokuqina kwe-Rockwell elilinganisiwe liphansi kakhulu, okuholela ekuhlolweni okungavumelekile.

Ngokusho kwe-GB/T 230.1-2018 «Ukuhlolwa Kokuqina Kwezinto Zensimbi eRockwell Ingxenye 1: Indlela Yokuhlola», ubulukhuni beRockwell bungu-80HRBW kanti ubuncane besampula bungu-1.5mm. Ubuncane besampula No. 1 bungu-1.65mm, ubuncane besendlalelo esikhishwe i-carburing bungu-0.15~0.20mm, kanti ubuncane besampula ngemva kokususa ungqimba olukhishwe i-carburing bungu-1.4~1.45mm, obuseduze nobuncane besampula obuchazwe ku-GB/T 230.1-2018. Ngesikhathi sokuhlolwa, njengoba kungekho ukwesekwa phakathi kwesampula, kuzobangela ukuguquguquka okuncane (okungase kungabonwa ngamehlo enyama), ngakho-ke inani langempela lobulukhuni beRockwell liphansi.

2) Indlela yokukhetha isihloli sobulukhuni bomphezulu wamapayipi ensimbi:

Ngemva kokuhlolwa okuningi kobulukhuni bomphezulu wamapayipi ensimbi, inkampani yethu ifinyelele eziphethweni ezilandelayo:

1. Lapho kwenziwa ukuhlolwa kobulukhuni be-Rockwell noma ukuhlolwa kobulukhuni be-Rockwell ebusweni bamapayipi ensimbi anodonga oluncane, ukusekelwa okunganele kodonga lwepayipi kuzobangela ukuguguleka kwesampula futhi kuholele emiphumeleni yokuhlolwa ephansi;

2. Uma kufakwa ukwesekwa okuyisilinda phakathi kwepayipi lensimbi elinodonga oluncane, imiphumela yokuhlolwa izoba phansi ngoba i-axis yekhanda lokucindezela kanye nesiqondiso somthwalo akukwazi ukuqinisekiswa ukuthi kuqondile ebusweni bepayipi lensimbi, futhi kukhona igebe phakathi kobuso bangaphandle bepayipi lensimbi kanye nokusekelwa okuyisilinda okufakiwe.

3. Indlela yokuguqula ubulukhuni be-Vickers obulinganisiwe bube ubulukhuni be-Rockwell ngemva kokufaka nokupholisha isampula yepayipi lensimbi inembile kakhulu.

4. Ngemva kokususa isikali se-oxide kanye nesendlalelo sokususa i-carburization ebusweni bepayipi lensimbi kanye nokucubungula indiza yokuhlola ebusweni bangaphandle bese uyibeka ngaphakathi, ubulukhuni be-Rockwell buguqulwa bube ubulukhuni be-Rockwell, obunembile kakhulu.

Isikhathi sokuthunyelwe: Juni-13-2024