1) Ingabe isihloli sokuqina kweRockwell singasetshenziswa ukuhlola ubulukhuni bodonga lwepayipi lensimbi?

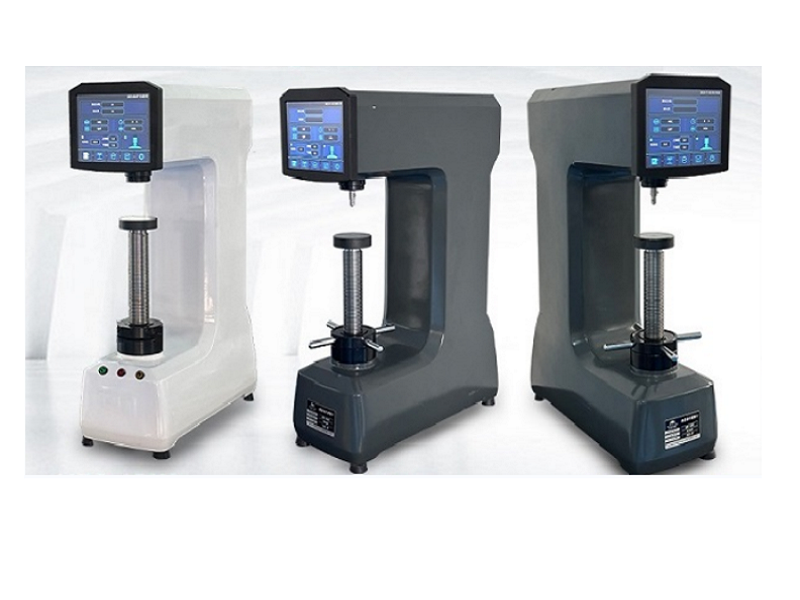

Izinto zokuhlola ziyipayipi lensimbi le-SA-213M T22 elinobubanzi bangaphandle obungu-16mm kanye nobukhulu bodonga obungu-1.65mm. Imiphumela yokuhlolwa kwesihloli sokuqina kwe-Rockwell imi kanje: Ngemva kokususa i-oxide kanye nengqimba ekhishwe i-carburised ebusweni besampula nge-grinder, isampula yabekwa etafuleni lokusebenza elinomfanekiso ongu-V kanti ukuhlolwa kokuqina kwe-Rockwell kwenziwa ngqo ebusweni balo bangaphandle, kusetshenziswa isihloli sokuqina kwe-HRS-150S sedijithali se-Rockwell kumthwalo:980.7N.

Ngemva kokuhlolwa, kungabonakala ukuthi ipayipi lensimbi odongeni linokuguquguquka okuncane, futhi umphumela uba ukuthi: inani eliphansi elilinganiswe ngokuqina kweRockwell lenza ukuhlolwa kungasebenzi.

Ngokusho kwe-GB/T 230.1-2018 « Ukuhlolwa kokuqina kweRockwell kwezinto zensimbi Ingxenye 1: Izindlela zokuhlola », ubulukhuni beRockwell bungu-80HRBW kanti ubuncane bobukhulu besampula bungu-1.5mm. Ubuncane besampula No.1 bungu-1.65mm, ubuncane besendlalelo esikhishwe i-carburing bungu-0.15~0.20mm, kanti ubuncane besampula ngemva kokususa ungqimba olukhishwe i-carburing bungu-1.4~1.45mm, okuseduze nobukhulu obuncane besampula obuchazwe ku-GB/T 230.1-2018.

Ngesikhathi sokuhlolwa, ngenxa yokuthi isikhungo sesampula asisekelwa, kuzobangela ukuguquguquka okucashile (mhlawumbe okungabonakali ngeso lenyama), ngakho-ke inani elilinganisiwe lokuqina kweRockwell liphansi impela.

2) Indlela yokukhetha okungaphezuluRockwellumhloli wobulukhuni wokuhlola amapayipi ensimbi:

Inkampani yethu ihlole ngokuphindaphindiwe ubulukhuni bomphezulu wepayipi lensimbi futhi yafinyelela eziphethweni ezilandelayo.:

Ukuhlolwa kobulukhuni be-Rockwell okungaphezulu noma ukuhlolwa kobulukhuni be-Rockwell ebusweni bepayipi lensimbi elinodonga oluncane. Ukusekelwa okwanele kodonga kuzobangela ukuguquguquka kwesampula futhi kuholele emiphumeleni yokuhlolwa ephansi;

Uma ubeka ukwesekwa kwesilinda phakathi kwepayipi lensimbi elinodonga oluncane, ngoba alikwazi ukuqinisekisa ukuthi i-indenter axis kanye nesiqondiso sokulayisha umthwalo kanye nobuso bepayipi lensimbi buqondile ebusweni, kanye nobuso bangaphandle bepayipi lensimbi futhi lapho kuzobangela igebe lokusekelwa kwesilinda kwegebe phakathi kobuso obuyindilinga bepayipi lensimbi kanye nobuso obuyindilinga bokusekela kwesilinda, kuzophinde kubangele ukuthi umphumela wokuhlolwa uphansi kakhulu.

Guqula ukuhlolwa kobulukhuni be-Vickers kube ukuhlolwa kobulukhuni be-Rockwell ngemuva kokupholisha isampula yepayipi lensimbi, uzothola inani lobulukhuni be-Rockwell elinembile.

2. Ngemva kokususa ungqimba lwe-oxide kanye ne-decarburization ebusweni bepayipi lensimbi bese ulungisa indiza yokuhlola ebusweni bangaphandle bese uyibeka ngaphakathi, Inani linembile kakhulu uma liqhathaniswa ne-Superficial Rockwell hardness tester ne-Rockwell hardness tester.

Isikhathi sokuthunyelwe: Meyi-28-2024