Kunezinhlobo eziningi zezingubo zensimbi. Izingubo ezahlukene zidinga amandla ahlukene okuhlola ekuhlolweni kokuqina kwe-micro, futhi amandla okuhlola awakwazi ukusetshenziswa ngokungahleliwe. Esikhundleni salokho, ukuhlolwa kufanele kwenziwe ngokuhambisana namanani amandla okuhlola anconywe yizindinganiso. Namuhla, sizokwethula ikakhulukazi ukuhlolwa kokuqina kwe-micro Vickers kwezingubo ze-zinc noma izambatho ze-zinc-aluminium-magnesium alloy ezisetshenziswa ensimbini.

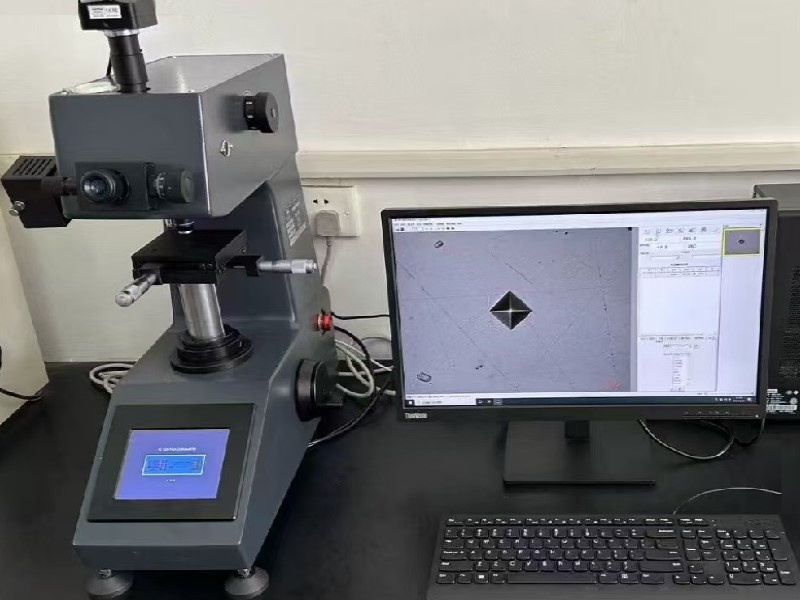

1. Ukulungiselela amasampula e-metallographic asezingeni eliphezulu ezimbozo ze-zinc (noma izimbozo ze-aluminium-magnesium) yisinyathelo sokuqala sokuhlola ukumboza. Ukulungiswa kwamasampula okumboza i-zinc kuhilela izinyathelo eziningi, okuhlanganisa ukusampula, ukufaka, kanye nokugaya nokupholisha kusengaphambili. Inhloso yokulungiselela amasampula anjalo ukugaya ubuso obunqamula ingxenye yomsebenzi bube yindawo ebushelelezi, eyisicaba evumela ukubonakala okucacile kwezimbozo ze-Vickers, okwenza kube lula ukulinganisa ngokunembile ubukhulu bokumboza ukuze kutholakale amanani obulukhuni.

2. Ukuhlolwa kobulukhuni be-zinc coatings: njengoba i-zinc coatings ikhulu kakhulu, ukuhlolwa kobulukhuni kungenziwa ngamandla okuhlola ahlukene. Kusampula efanayo, uma amandla okuhlola amancane asetshenziswayo, usayizi wokugoba uncane; ngokuphambene nalokho, uma amandla okuhlola emakhulu, usayizi wokugoba ukhulu. Uma i-coat ezungeze i-indenti ibonisa izimpawu zokuqhekeka noma zokuguquka, kufanele kukhethwe amandla amancane okuhlola. Le nqubo iphindaphindwa kuze kube yilapho i-coat ezungeze i-Vickers coatings ihlala ingashintshi ngaphandle kokuguquka—leli zinga lamandla okuhlola yilona elifanele isampula.

2.1 Ubukhulu obuhlukene bokumboza buhambisana nobubanzi bamandla okuhlola athile, okubalulekile ekugwemeni ukuhlanekezelwa kwemiphumela yokuhlolwa. Okulandelayo kuyinkomba yokukhethwa kwamandla okuhlola kwezingubo ezivamile (i-zinc plating, i-chromium plating), esebenza kubahloli bokuqina be-micro Vickers (HV):

| Uhlobo Lokumboza | Ukugqoka Ubukhulu (μm) | Ncoma Amandla Okuhlola (gf) | Okuhambisanayo Isikali se-HV | Izinyathelo Zokuqapha Eziyinhloko |

| I-Zinc Ukubeka iplati | 5 ~ 15 | 25 ~ 50 | HV0.025, HV0.05 | I-zinc plating ithambile (ngokuvamile i-HV50~150); amandla amancane avimbela ukugoba ngokweqile. |

| I-Zinc Ukubeka iplati | 15 ~ 50 | 50 ~ 100 | HV0.05, HV0.1 | Njengoba ukujiya kwanda, amandla angaphakanyiswa ngendlela efanele ukuqinisekisa ukuthi imiphetho yokugoba icacile. |

| I-Chromium Ukubeka iplati | 1 ~ 5 | 10 ~ 25 | HV0.01, HV0.025 | I-chromium eqinile (HV800~1200) inobulukhuni obuphezulu; amandla amancane avimbela umonakalo we-indenter. |

| I-Chromium Ukubeka iplati | 5 ~ 20 | 25 ~ 100 | HV0.025, HV0.1 | Uma ukujiya kungu->10μm, i-HV0.1force ilinganisa ukunemba nokusebenza kahle. |

| Inhlanganisela Ukugqoka | <5 | ≤25 | HV0.01, HV0.025 | Ngezimbozo ezifana ne-zinc-nickel alloy kanye ne-chromium-nickel alloy, vimbela ngokuqinile ukungena kwe-inbound ku-coating. |

2.2 Ezinye Izinto Ezibalulekile Ezithonyayo

Ngaphezu kobukhulu, lezi zici ezimbili ezilandelayo zizoqhubeka nokushintsha ukukhethwa kwamandla okuhlola, futhi zidinga ukwahlulela ngokusekelwe ezimweni zangempela:

Ububanzi Bokuqina Kokumboza:

Ukumbozwa okuthambile (isb., i-zinc plating, i-HV < 200): Uma amandla okuhlola emancane kakhulu, ukugoba kungase kufiphale ngenxa yokuguqulwa kwepulasitiki kokumbozwa. Kunconywa ukukhetha umkhawulo ophezulu wobubanzi obunconywayo (njengokujiya okungu-10 μm, khetha amandla okuhlola angu-50gf).

Izimbozo eziqinile (isb., i-chromium plating, i-HV > 800): Ubulukhuni obuphezulu buholela ekungeneni okuncane, ngakho-ke amandla okuhlola akufanele abe mancane kakhulu (njengokuthi, ubukhulu obungu-5 μm, khetha amandla okuhlola angu-25gf) ukuvimbela iphutha lokulinganisa le-diagonal ye-indentation ukuthi ingadluli ku-±5%.

2.3 Izidingo Zezindinganiso Nezincazelo

Izimboni ezahlukene zinezindinganiso ezicacile. Isibonelo:

Imboni yezimoto ivame ukusebenzisa i-ISO 14577 (Instrumented Indentation Test), evumela ukulungisa inani lamandla ngokuya ngobukhulu bengubo;

Imboni evamile ibhekisela ku-ASTM E384, edinga ukuthi i-diagonal ye-indentation ibe yi-≤ 1/2 yobukhulu be-coating kanye ne-≥ izikhathi eziyi-10 kune-radius ye-indent tip (ukugwema umphumela we-tip).

Ekuphetheni, ukukhethwa kwamandla okuhlola ukuhlolwa kobulukhuni be-micro-Vickers kwezembozo zensimbi kufanele kulandele umqondo othi “ukujiya kuqala, ukulungiswa kobulukhuni, kanye nesiqinisekiso esijwayelekile”:

Okokuqala, nquma ububanzi bamandla okuhlola ngokusekelwe ekujikeni kokumboza (bheka ithebula elingenhla);

Lungisa inani lamandla ngokuya ngobulukhuni bengubo (khetha umkhawulo ophezulu wezingubo ezithambile kanye nomkhawulo ophansi wezingubo eziqinile);

Okokugcina, vumelana nezindinganiso zemboni (njenge-ISO 14577 kanye ne-ASTM E384) ukuqinisekisa ukusebenza kwemiphumela yokuhlolwa.

Isikhathi sokuthunyelwe: Septhemba-03-2025