Njengoba sonke sazi, indlela ngayinye yokuhlola ubulukhuni, kungakhathaliseki ukuthi iBrinell, Rockwell, Vickers noma i-capable Leeb hardness tester, inemikhawulo yayo futhi ayinamandla onke. Kuma-workpiece amakhulu, asindayo futhi angajwayelekile e-geometric njengaleyo eboniswe esibonelweni esilandelayo, izindlela eziningi zokuhlola zamanje zisebenzisa ama-capable Leeb hardness testers ukulawula ubulukhuni bawo.

Indlela yokulinganisa enamandla yesihloli sokuqina kweLeeb inezici eziningi ezithinta ukunemba kwayo kokuqina: njengokuthi: i-modulus ye-elastic yezinto ezibonakalayo, ukusetshenziswa kwekhanda lebhola, ubulukhuni bomphezulu we-workpiece, i-radius egobile, ukujula kwengqimba eqinile yomphezulu, njll. Uma kuqhathaniswa nezindlela zokulinganisa ezimile zikaBrinell, Rockwell noVickers, iphutha likhulu kakhulu. Uma ubulukhuni budinga ukunemba okuphezulu, kufanele sikhethe kanjani isihloli sokuqina?

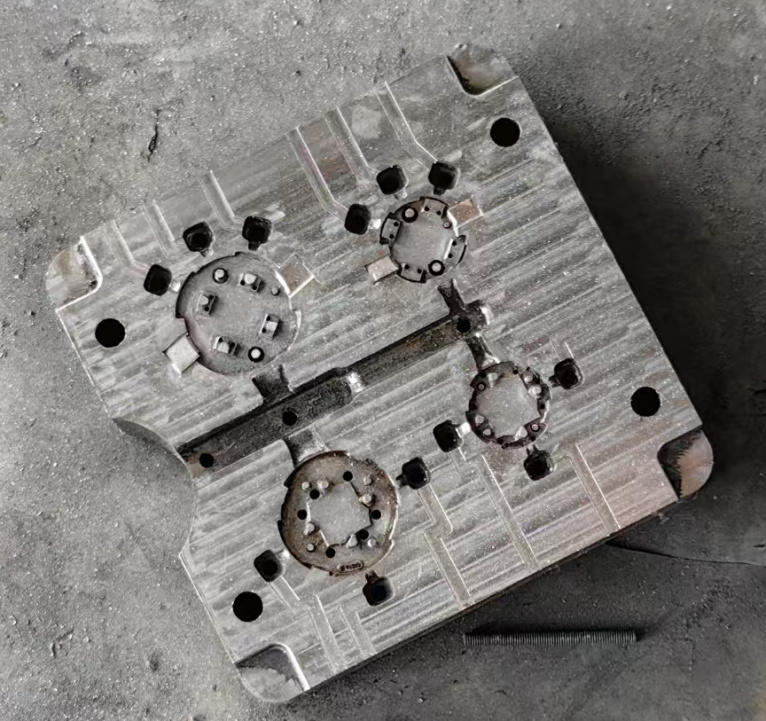

Lolu hlobo lomsebenzi osindayo enkambisweni yokuhlola ubulukhuni obujwayelekile, ngaphambi kokulayisha nokukhipha isivivinyo sokuhlola ubulukhuni, kanye nokukhipha isivivinyo sokuhlola ubulukhuni kuzoletha umthwalo omkhulu womsebenzi enkambisweni yokusebenza, ngakho-ke sikhetha kanjani isivivinyo sokuhlola ubulukhuni? Okulandelayo kuncoma ukusetshenziswa kwesivivinyo sokuhlola ubulukhuni esinesakhiwo sokuphakamisa ikhanda ukuqedela yonke inqubo yokuhlola. Njengoba kuboniswe ngezansi:

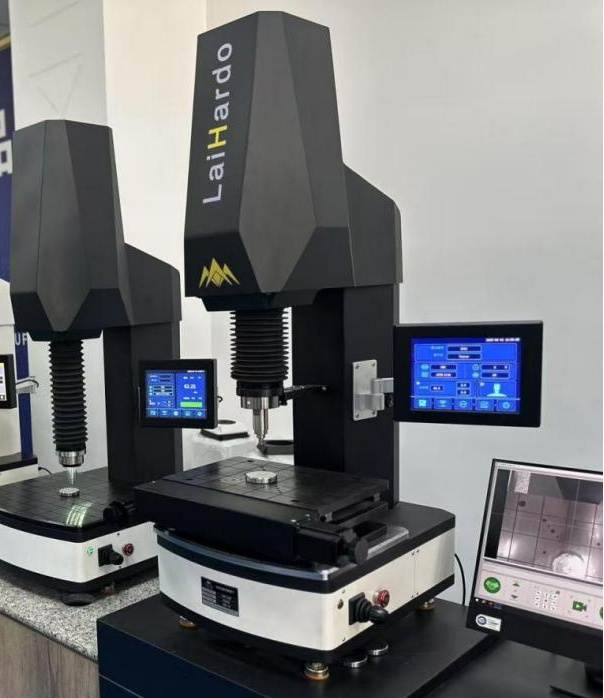

Lesi sixazululo sokuhlola ubulukhuni singafeza ukuhlolwa kobulukhuni kweRockwell/Vickers kanye nokuhlolwa kobulukhuni kweBrinell ngokuya ngezindinganiso zokuhlola ubulukhuni (GB/T 231.1, GB/T 4340.1, ISO6507, ISO6508, ASTM E18, njll.), futhi sihlangabezane nezidingo zokuhlolwa okunembe kakhulu kanye nokukhiqiza okuphumelelayo kwezingxenye zokusebenza ezisindayo.

Umhloli wokuqina kokuphakamisa ikhanda okuzenzakalelayo unebhentshi lokusebenzela elingaguquki, elinciphisa iphutha elibangelwa yisikulufu kanye nokuphakamisa ibhentshi lokusebenzela kuze kube ukunemba kokulinganisa ubunzima. Ibhentshi lokusebenzela likhulu ngobukhulu futhi lingamukela izingcezu zokusebenza ezinkulu ezinesisindo. Ukulinganisa kwenkinobho eyodwa kunciphisa kakhulu iphutha lokuhlola kanye nomsebenzi womhloli, okulula futhi okusheshayo.

Isikhathi sokuthunyelwe: Ephreli-23-2025