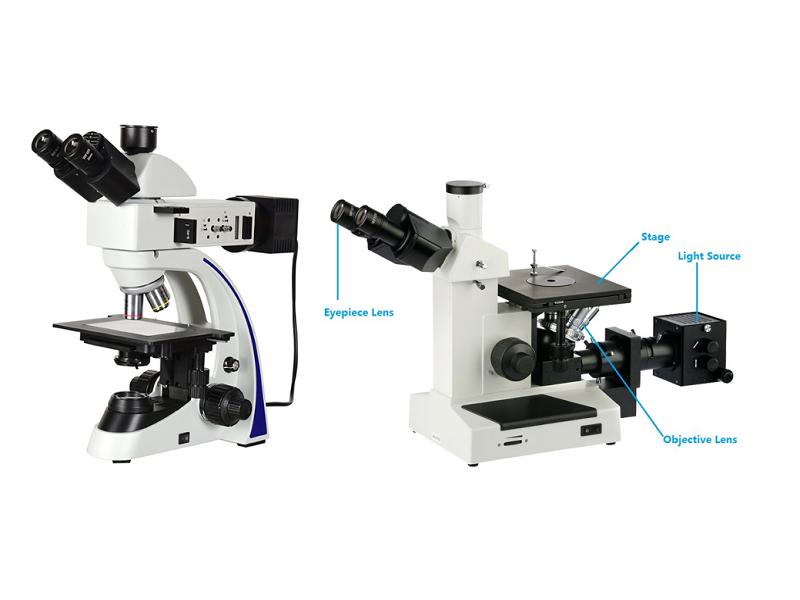

1. Namuhla ake sibone umehluko phakathi kwama-microscope e-metallographic aqondile nalawo aguquliwe: Isizathu sokuthi i-microscope ye-metallographic eguquliwe ibizwa ngokuthi i-inverted ukuthi ilensi eqondile ingaphansi kwesiteji, futhi umsebenzi udinga ukuphendulwa ubheke phansi esiteji ukuze kubonwe futhi kuhlaziywe. Ifakwe kuphela uhlelo lokukhanyisa olukhanyayo, olufaneleka kakhulu ekubukeni izinto zensimbi.

I-microscope ye-metallographic eqondile inelensi eqondile esiteji futhi umsebenzi ubekwa esiteji, ngakho-ke ibizwa ngokuthi iqondile. Ingafakwa uhlelo lokukhanyisa oludluliselwayo kanye nohlelo lokukhanyisa olubonakalayo, okungukuthi, imithombo emibili yokukhanya ngaphezulu nangaphansi, engabona amapulasitiki, irabha, amabhodi wesekethe, amafilimu, ama-semiconductor, izinsimbi nezinye izinto.

Ngakho-ke, esigabeni sokuqala sokuhlaziywa kwe-metallographic, inqubo yokulungiselela isampula eguquliwe idinga kuphela ukwenza ubuso obubodwa, okulula kunebo obuqondile. Iningi lezimboni zokwelashwa kokushisa, ukucubungula, imikhiqizo yensimbi kanye nemishini zikhetha ama-microscope e-metallographic aguquliwe, kuyilapho amayunithi ocwaningo lwesayensi ekhetha ama-microscope e-metallographic aqondile.

2. Izinyathelo zokuphepha zokusebenzisa i-metallographic microscope:

1) Kufanele sinake okulandelayo lapho sisebenzisa le microscope ye-metallographic esezingeni locwaningo:

2) Gwema ukubeka imakroskopu ezindaweni ezinelanga eliqondile, izinga lokushisa eliphezulu noma umswakama ophezulu, uthuli, kanye nokudlidliza okunamandla, futhi uqinisekise ukuthi indawo yokusebenza iyisicaba futhi iqondile

3) Kudinga abantu ababili ukuhambisa imakroskopu, umuntu oyedwa ubamba ingalo ngezandla zombili, kanti omunye ubamba ingxenye engezansi yomzimba wemakroskopu bese eyibeka ngokucophelela.

4) Uma uhambisa imakroskopu, ungabambeli isigaba samakroskopu, i-focus knob, i-observation tube, kanye nomthombo wokukhanya ukuze ugweme ukulimala kwemakroskopu

5) Ubuso bomthombo wokukhanya buzoshisa kakhulu, futhi kufanele uqinisekise ukuthi kunesikhala esanele sokusabalalisa ukushisa eduze komthombo wokukhanya.

6) Ukuqinisekisa ukuphepha, qiniseka ukuthi inkinobho eyinhloko iku-"O" ngaphambi kokushintsha isibani noma i-fuse

Isikhathi sokuthunyelwe: Agasti-01-2024