1 Ukulungiselela ngaphambi kokuhlolwa

1) Isihloli sobulukhuni kanye ne-indenter esetshenziselwa ukuhlolwa kobulukhuni be-Vickers kufanele ihambisane nemibandela ye-GB/T4340.2;

2) Izinga lokushisa legumbi ngokuvamile kufanele lilawulwe ngaphakathi kwebanga elingu-10~35℃. Ekuhlolweni okunezidingo zokunemba okuphezulu, kufanele lilawulwe ku-(23±5)℃.

Amasampula ama-2

1) Ubuso besampula kufanele bube bushelelezi futhi bube bushelelezi. Kunconywa ukuthi ubulukhuni bobuso besampula kufanele buhlangabezane nezidingo: Inani eliphakeme kakhulu lepharamitha yobulukhuni bobuso: Isampula yobunzima be-Vickers 0.4 (Ra)/μm; isampula yobunzima be-Vickers yomthwalo omncane 0.2 (Ra)/μm; isampula yobunzima be-micro Vickers 0.1 (Ra)/μm

2) Kumasampula e-Vickers amancane kanye nama-micro Vickers, kunconywa ukukhetha ukupholisha okufanele kanye nokupholisha nge-electrolytic ukuze kuphathwe ubuso ngokuya ngohlobo lwezinto.

3) Ubukhulu besampula noma ungqimba lokuhlola kufanele okungenani bube ubude obuphindwe ka-1.5 kunobude obuqondile bokugoba

4) Uma usebenzisa umthwalo omncane kanye nama-micro Vickers ukuhlola, uma isampula incane kakhulu noma ingajwayelekile, isampula kufanele ifakwe noma iboshwe nge-fixture ekhethekile ngaphambi kokuhlola.

3Indlela yokuhlola

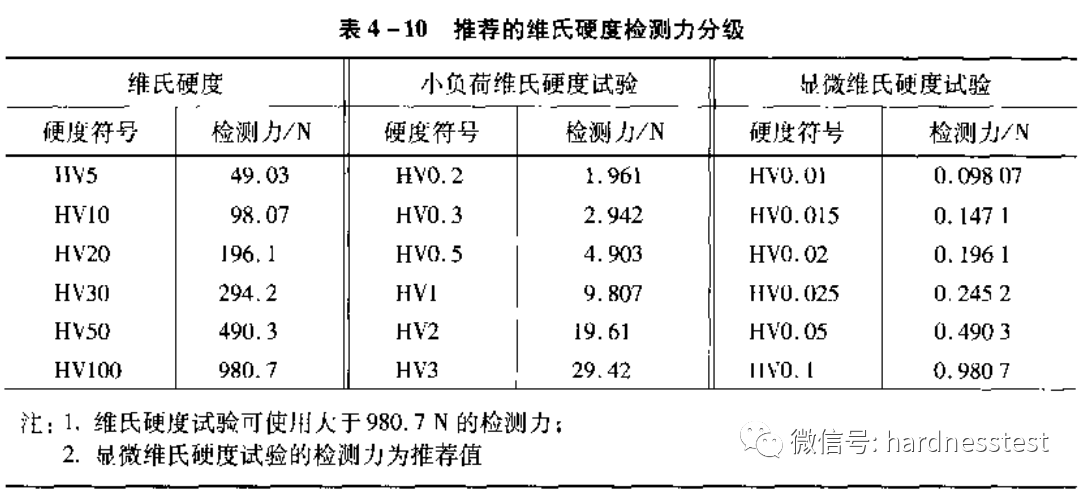

1) Ukukhethwa kwamandla okuhlola: Ngokusho kobulukhuni, ukujiya, usayizi, njll. wesampula, amandla okuhlola aboniswe kuThebula 4-10 kufanele akhethwe ukuze kuhlolwe.

2) Isikhathi sokufaka amandla okuhlola: Isikhathi kusukela ekuqaleni kokufaka amandla kuze kube sekuqedweni kokufaka amandla okuhlola okuphelele kufanele sibe phakathi kwemizuzwana emi-2 ~ 10. Kuma-Vickers amancane omthwalo kanye nokuhlolwa kobulukhuni be-micro Vickers, isivinini sokwehla kwe-indenter akufanele sidlule u-0.2 mm/s. Isikhathi sokubamba amandla okuhlola singamasekhondi ayi-10 ~ 15. Kwezinto ezithambile ikakhulukazi, isikhathi sokubamba singandiswa, kodwa iphutha kufanele libe phakathi kwemizuzwana emi-2.

3) Ibanga elisuka enkabeni yokugoba kuya emaphethelweni esampula: Izinsimbi zensimbi, zethusi nezethusi kufanele okungenani zibe ubude obuphindwe ka-2.5 be-diagonal bokugoba; izinsimbi ezikhanyayo, i-lead, i-tin kanye ne-alloys yazo kufanele okungenani zibe ubude obuphindwe ka-3 be-diagonal bokugoba. Ibanga eliphakathi kwezikhungo ze-indenti ezimbili eziseduze: zensimbi, zethusi kanye ne-alloys zethusi, kufanele okungenani zibe ubude obuphindwe ka-3 bomugqa oqondile we-stop mark; zezinsimbi ezikhanyayo, i-lead, i-tin kanye ne-alloys zazo, kufanele okungenani zibe ubude obuphindwe ka-6 bomugqa oqondile we-indenti.

4) Linganisa isilinganiso sezibalo sobude bama-diagonal amabili e-indentation, bese uthola inani lobulukhuni be-Vickers ngokwethebula, noma ubale inani lobulukhuni ngokwefomula.

Umehluko ebudeni be-diagonal ezimbili ze-indentation endizeni akufanele udlule u-5% wenani elimaphakathi le-diagonal. Uma lidlula, kufanele liphawulwe embikweni wokuhlola.

5) Uma kuhlolwa kusampula yobuso obugobile, imiphumela kufanele ilungiswe ngokwethebula.

6) Ngokuvamile, kunconywa ukubika amanani okuhlolwa kobulukhuni bamaphuzu amathathu kwisampula ngayinye.

Ukuhlukaniswa kobulukhuni be-Vickers okungu-4

Kunezinhlobo ezimbili zabahloli bokuqina be-Vickers abavame ukusetshenziswa. Okulandelayo yisingeniso sokusetshenziswa kwabahloli bokuqina be-Vickers abavame ukusetshenziswa:

1. Uhlobo lokulinganisa i-eyepiece;

2. Uhlobo lokulinganisa isofthiwe

Isigaba 1: Uhlobo lokulinganisa i-eyepiece Izici: Sebenzisa i-eyepiece ukukala. Ukusetshenziswa: Umshini wenza i-inbot (idayimane ◆), bese ubude obuqondile bedayimane bulinganiswa nge-eyepiece ukuthola inani lobunzima.

Isigaba 2: Uhlobo lokulinganisa lwesofthiwe:Izici: Sebenzisa isofthiwe yokuqina ukuze ulinganise; kulula futhi kulula emehlweni; ingalinganisa ubulukhuni, ubude, igcine izithombe zokuqina, imibiko yezinkinga, njll. Ukusetshenziswa: Umshini wenza ukugoba (idayimane ◆), bese ikhamera yedijithali iqoqa ukugoba kukhompyutha, bese inani lobulukhuni lilinganiswa kukhompyutha.

5Ukuhlukaniswa kwesofthiwe: Izinguqulo eziyisisekelo ezi-4, inguqulo yokulawula i-turret ezenzakalelayo, inguqulo ezenzakalelayo kancane, kanye nenguqulo ezenzakalelayo ngokuphelele.

1. Inguqulo eyisisekelo

Ingalinganisa ubulukhuni, ubude, igcine izithombe zokungena, imibiko yezinkinga, njll.;

2. Isofthiwe yenguqulo ye-turret ezenzakalelayo yokulawula ingalawula i-turret yokuhlola ubulukhuni, njenge-lens eqondile, i-indenter, ukulayisha, njll.;

3. Inguqulo ezenzakalelayo kancane enetafula lokuhlola le-XY kagesi, ibhokisi lokulawula leplatifomu le-2D; Ngaphezu komsebenzi wenguqulo ye-turret ezenzakalelayo, isofthiwe ingaphinde isethe izikhala kanye namaphoyinti, amachashazi azenzakalelayo, ukulinganisa okuzenzakalelayo, njll.;

4. Inguqulo ezenzakalelayo ngokugcwele enetafula lokuhlola le-XY kagesi, ibhokisi lokulawula leplatifomu le-3D, ukugxila kwe-Z-axis; Ngaphezu komsebenzi wenguqulo ezenzakalelayo, isofthiwe iphinde ibe nomsebenzi wokugxila kwe-Z-axis;

6Indlela yokukhetha isihloli sokuqina kwe-Vickers esifanele

Intengo yesihloli sokuqina kwe-Vickers izohluka kuye ngokucushwa kanye nomsebenzi.

1. Uma ufuna ukukhetha okushibhile, ungakhetha:

Imishini enesikrini esincane se-LCD kanye nokufakwa kwe-diagonal ngesandla nge-eyepiece;

2. Uma ufuna ukukhetha idivayisi engabizi kakhulu, ungakhetha:

Imishini enesikrini esikhulu se-LCD, i-eyepiece ene-encoder yedijithali, kanye nephrinta eyakhelwe ngaphakathi;

3. Uma ufuna idivayisi esezingeni eliphezulu, ungakhetha:

Imishini enesikrini sokuthinta, inzwa evaliwe, i-eyepiece enephrinta (noma i-USB flash drive), isikulufu sokuphakamisa amagiya e-worm, kanye ne-encoder yedijithali;

4. Uma ucabanga ukuthi kuyakhathaza ukukala nge-eyepiece, ungakhetha:

Ifakwe uhlelo lokucubungula izithombe zokuqina kwe-CCD, kala kukhompyutha ngaphandle kokubheka i-eyepiece, elula, enembile, futhi esheshayo. Ungakha futhi imibiko futhi ulondoloze izithombe zokungena, njll.

5. Uma ufuna ukusebenza okulula kanye nokwenza izinto ngokuzenzakalela okuphezulu, ungakhetha:

Umhloli wobulukhuni be-Vickers ozenzakalelayo kanye nomhloli wobulukhuni be-Vickers ozenzakalelayo ngokuphelele

Izici: setha isikhala kanye nenani lamaphuzu, ngokuzenzakalela nangokuqhubekayo amachashazi, bese ulinganisa ngokuzenzakalelayo.

Isikhathi sokuthunyelwe: Okthoba-17-2024