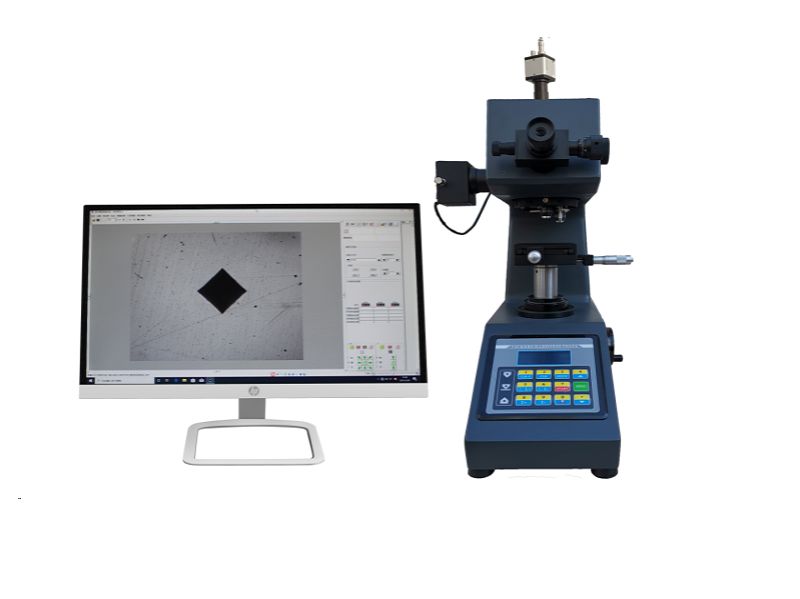

Ukuqina endaweni ezungeze i-weld kungasiza ekuhloleni ubuthakathaka be-weld, ngaleyo ndlela kukusize ukuthi unqume ukuthi i-weld inamandla adingekayo yini, ngakho-ke indlela yokuhlola ubulukhuni be-weld i-Vickers iyindlela esiza ekuhloleni ikhwalithi ye-weld.

Umhloli wobulukhuni we-Vickers we-Shandong Shancai / Laizhou Laihua Testing Instrument Company angenza ukuhlolwa kobulukhuni ezingxenyeni ezihlanganisiwe noma ezindaweni zokushisela. Lapho kuhlolwa ubulukhuni bendawo yokushisela, kuzolinganiswa ngamaphuzu amaningi ebangeni elithile ukusuka emaphethelweni esampula noma phezulu kwendawo yokushisela. Ngemva kokuthola ukujiya kwamaphuzu amaningi, inani lobulukhuni lingalinganiswa ngokulinganisa okuqhubekayo futhi kungatholakala igrafu yejika.

Uma usebenzisa isihloli sokuqina kwe-Vickers ukuhlola izingxenye ezihlanganisiwe, kufanele kuqashelwe izimo zokuhlola ezilandelayo:

1. Ukuthamba kwesampula: Ngaphambi kokuhlola, sigaya i-weld ezohlolwa ukuze senze ubuso bayo bube bushelelezi, bungabi nongqimba lwe-oxide, imifantu nezinye izinkinga.

2. Emugqeni ophakathi nendawo we-weld, thatha iphuzu endaweni egobile njalo nge-100 mm ukuze uvivinye.

3. Ukukhetha amandla okuhlola ahlukene kuzoholela emiphumeleni ehlukene, ngakho-ke kumelwe sikhethe amandla okuhlola afanele ngaphambi kokuhlola.

Umhloli wokuqina kwe-micro unezidingo zokuqeda ubuso besampula evivinyiwe, okudingeka kulungiselelwe ngokucophelela ngokwesampula ye-metallographic.

Umgomo wokuhlola ubulukhuni obuncane endleleni yokuhlola ubulukhuni obuncane ufana ncamashi nobunzima be-Vickers, kodwa umthwalo osetshenziswayo mncane kunobunzima be-Vickers obunomthwalo ophansi, ngokuvamile ungaphansi kuka-1000g, futhi ukugoba okubangelwayo kungama-micron ambalwa kuya kuma-micron amabili ambalwa, ngakho-ke ukuhlolwa kobulukhuni obuncane kunikeza indlela elula kakhulu yokufunda izakhiwo zesakhiwo esincane somendlalelo ongenela amanzi. Kusetshenziswa kabanzi ukunquma ubulukhuni besigaba ngasinye ebusweni kanye nasesendlaleloni esingenela amanzi.

Uphawu lokuqina okuncane luvame ukuvezwa yi-HV, futhi isimiso salo sokunquma kanye nendlela yalo kufana nendlela yokuqina kwe-Vickers. Uhlelo lokulayisha, uhlelo lokulinganisa kanye nokunemba kwe-indenter kwesihloli sokuqina okuncane kufuna kakhulu kunolomhloli wokuqina kwe-Vickers onemithwalo ephansi. Njengamanje, isihloli sokuqina okuncane sisetshenziswa kabanzi ezintweni zokusebenza ezincane, futhi ngenxa yokuthi ukukhulisa kungafinyelela izikhathi ezingu-400, kuvame ukusetshenziswa njenge-microscope elula ye-metallographic.

Enkambisweni yokusebenzisa, kufanele kuqashelwe umthwalo, i-micrometer kanye ne-indenter yesihloli sokuqina kwe-micro, okufanele kuhlolwe ngaphambi kokusetshenziswa, futhi ibhlogo lokuqina lisetshenziselwa ukuhlonza ngokuphelele inani lalo elibonisayo.

Umhloli wokuqina kwe-micro usebenzisa umthwalo ekusebenzeni kokuhlolwa ngendlela ebushelelezi nefana ngangokunokwenzeka, ngaphandle kokuthintana nokudlidliza. Ukuze kuqinisekiswe ukunemba kwemiphumela yokuhlolwa, ngokuvamile kuyadingeka ukukala izikhathi eziningana ezingxenyeni ezahlukene, bese uthola inani elimaphakathi elimele inani lokuqina kwesendlalelo sokuhlola ukuvuleka noma isigaba se-alloy. Ngesendlalelo sokungena esisetshenziswa ekushiseni okuphezulu, ubunzima baso bungalinganiswa ngokusebenzisa umhloli wokuqina kwe-micro ekushiseni okuphezulu.

Isikhathi sokuthunyelwe: Ephreli-10-2024