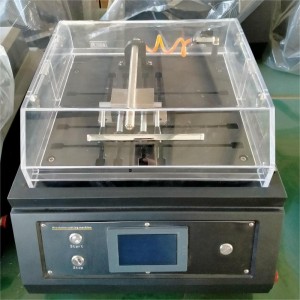

I-PQG-200 Metallographic Precision Flat Cutting Machine

I-PQG-200 metallographic precision flat cutting machine ifaneleka ukusika amasampula afana nama-semiconductors, amakristalu, amabhodi wesekethe, izinsimbi, izinto zensimbi, amatshe nezitsha zobumba. I-fuselage yomshini wonke ibushelelezi, ivulekile futhi ivulekile, inikeza isiteji esihle sokusebenza. Futhi yamukela i-torque ephezulu namandla aphezulu e-servo motor kanye nesistimu yokulawula isivinini eguquguqukayo, esebenza kahle kakhulu nokuzinza. Ukubonakala okuhle nekhono lokusika linciphisa ubunzima bokusebenza futhi kulula ukulisebenzisa. Ngaphezu kwalokho, umshini ufakwe izinto ezihlukahlukene ezihlukahlukene, ezingasika izinto zokusebenza ezimise okungajwayelekile. Iwumshini wokusika wekhwalithi ephezulu ofanele izikhungo zocwaningo lwesayensi namabhizinisi.

I-PQG-200 yohlobo lwe-metallographic precision flat cutting machine ingumshini wokusika iphethini eyisicaba owenzelwe amaphethini ayisicaba. Imishini inegumbi elikhulu lokusika elivikelayo elisobala, elingabuka inqubo yokusika intuitively.

Isikrini sokuthinta se-elekthronikhi, lungisa futhi ulawule ukuphotha okunemba okuphezulu, isivinini kanye nesivinini sokusika ukuphotha kanye nebanga lokusika, kulula ukulisebenzisa, kulula ukusebenza, nomsebenzi wokusika othomathikhi, nciphisa ukukhathala komsebenzi womqhubi, futhi uqinisekise ukuhambisana komshini wokusika isampula Kuyinto efanelekile yamabhizinisi nezikhungo zocwaningo lwesayensi ukuze zilungiselele amasampula ekhwalithi ephezulu.

| igama lomkhiqizo | I-PQG-200 |

| Y ukuhamba | 160mm |

| ukusika indlela | umugqa oqondile, ishayela |

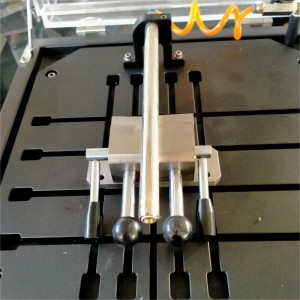

| I-blade yokusika idayimane (mm) | Φ200×0.9×32mm |

| Isivinini se-spindle (rpm) | 500-3000, kungenziwa egcizelele |

| Isivinini sokusika esizenzakalelayo | 0.01-3mm/s |

| Isivinini okwenziwa ngesandla | 0.01-15mm/s |

| Ibanga lokusika umthelela | 0.1-2mm/s |

| Maximum cutting ukujiya | 40mm |

| Ubude bokubopha obukhulu betafula | 585 mm |

| Ubukhulu bokubopha ububanzi betafula lokusebenza | 200mm |

| Bonisa | 5 inch touch all-in-one computer control |

| Isetshenziswa kanjani idatha | Izinhlobo eziyi-10 zingakhethwa |

| Usayizi wethebula (W×D,mm) | 500×585 |

| amandla | 600W |

| ukunikezwa kwamandla kagesi | Isigaba esisodwa 220V |

| Usayizi womshini | 530×600×470 |

Iphampu yamanzi yethangi lamanzi: isethi engu-1

isikhwama: 3pcs

Isikhwama somphimbo: 4pcs

ukusika izingcezu: 1pc (200*0.9*32mm)

Uketshezi lokusika: ibhodlela elingu-1

Intambo yamandla: 1pc

1. Le mishini ingaqedela ukusika okuzenzakalelayo. Sicela usethe amapharamitha afanelekile ngokuya ngezinto okufanele zisikwe ngaphambi kokusika.

2. Qiniseka ukuthi uvala umnyango we-warehouse ngaphambi kokuqala. Uma ingavaliwe, uhlelo lutshela ukuthi umnyango we-warehouse uvuliwe. Sicela uvale umnyango we-warehouse. Ngesikhathi sokusika, uma umnyango we-hatch uvuliwe, umshini uzoyeka ukusika. Uma ufuna ukuqhubeka nokusika, vala umnyango we-hatch bese ucindezela inkinobho yokuqala. Okokuqala, ipompo yamanzi iyasebenza, futhi ungabona ukuthi i-pump running indicator ikhanyisa, ilandelwa ukugijima kwe-spindle kanye nesivinini sokuphotha esibonisa Ukukhanya kuvuliwe, futhi ekugcineni ukukhanya kwenkomba yangaphambili kuvuliwe, futhi umsebenzi wokusika uyenziwa. Ngenxa yezizathu zokuphepha, kunconywa ukuthi ungavuli umnyango ngesikhathi sokusika umshini.

3. Ngemuva kokuqedwa kokusika, umshini uzohoxisa ngokuzenzakalelayo ummese bese ubuyela endaweni yokuqala yokuqala. Uma inkinobho yokumisa icindezelwa phakathi nenqubo yokusika, umshini uzongena esimweni sokuhoxisa ithuluzi futhi umlayezo uzosho ukuthi 'yima futhi uphume'. Ukuze uqinisekise ukuphepha, ungavuli umnyango ngesikhathi senqubo yokuhoxisa.

4. Uma udinga ukushintsha iblade yesaha, sicela ucindezele inkinobho yokumisa izimo eziphuthumayo noma uvale iswishi yamandla eyinhloko bese ulinda isikhashana ngenxa yezizathu zokuphepha. Ngemva kokushintshwa, khulula isitobhi esiphuthumayo noma uvule ugesi oyinhloko.

5. Ukugcwala kwesistimu noma i-alamu yesaha yesiqeshana kungase kubangelwe izizathu ezilandelayo:

(1) I-cutting saw blade ayifanele le nto yokusika, futhi i-cutting saw blade kufanele ishintshwe ngalesi sikhathi.

(2) Ijubane lokusika lishesha kakhulu, futhi isivinini sokusika kufanele sincishiswe ngalesi sikhathi.

(3) Le nto yokusika ayifanele lo mshini wokusika.