Ukwelashwa kokushisa okuphezulu kuhlukaniswe ngezigaba ezimbili: esinye ukwelashwa kokushisa okuphezulu kanye nokushisa okulinganiselwe, kanti esinye ukwelashwa kokushisa ngamakhemikhali. Indlela yokuhlola ubulukhuni yilena elandelayo:

1. ukwelashwa kokushisa okujulile nokushisa

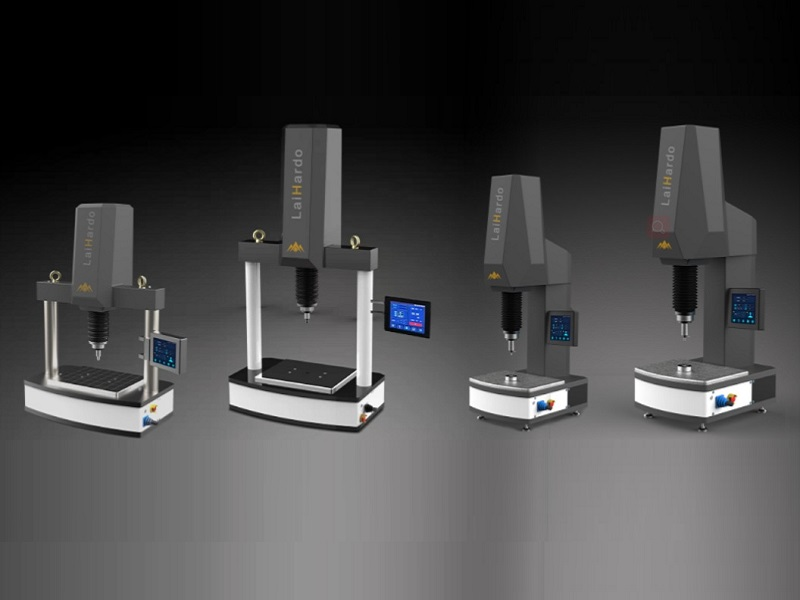

Ukwelashwa kokushisa okungaphezulu kanye nokushisa okulinganiselwe kuvame ukwenziwa ngokushisa okufakwayo noma ngokushisa ilangabi. Amapharamitha obuchwepheshe ayinhloko ubulukhuni obungaphezulu, ubulukhuni bendawo kanye nokujula kwezingqimba eziqinile okusebenzayo. Isihloli sobulukhuni seVickers noma isihloli sobulukhuni seRockwell singasetshenziswa ekuhlolweni kobulukhuni. Amandla okuhlola Ukukhetha kuhlobene nokujula kwengqimba eqinisiwe ephumelelayo kanye nobulukhuni obungaphezulu bento yokusebenza. Kunemishini emithathu yobulukhuni ehilelekile lapha.

(1) Isihloli sokuqina kwe-Vickers siyindlela ebalulekile yokuhlola ubulukhuni obungaphezulu bezinto zokusebenza eziphathwa ngokushisa. Singasebenzisa amandla okuhlola angu-0.5-100KG ukuhlola ungqimba lokuqina olungaphezulu oluncane njengobukhulu obungu-0.05mm. Ukunemba kwaso kuphakeme futhi singahlukanisa izinto zokusebenza eziphathwa ngokushisa. Umehluko omncane ebulukhuni obungaphezulu, ngaphezu kwalokho, ukujula kwengqimba eqinisiwe esebenzayo nakho kutholakala ngumhloli wokuqina kwe-Vickers, ngakho-ke kuyadingeka ukuhlomisa isihloli sokuqina kwe-Vickers ngamayunithi enza ukucubungula kokushisa okuphezulu noma asebenzise inani elikhulu lezinto zokusebenza zokwelashwa kokushisa okuphezulu.

(2) Isihloli sokuqina kwe-Rockwell esingaphezulu sifanelekile kakhulu ekuhloleni ubulukhuni besicubu esicwebezelayo esingaphezulu. Kunezikali ezintathu zesihloli sokuqina kwe-Rockwell esingaphezulu ongakhetha kuzo. Singahlola izicubu ezahlukene eziqinile ezingaphezulu okujula kwazo okusebenzayo okungaphezu kuka-0.1mm. Nakuba ukunemba kwesihloli sokuqina kwe-Rockwell esingaphezulu kungephezulu njengokwesihloli sokuqina kwe-Vickers, singahlangabezana nezidingo njengendlela yokuthola ukuphathwa kwekhwalithi kanye nokuhlolwa kweziqu zezitshalo zokwelapha ukushisa. .Ngaphandle kwalokho, sinezici zokusebenza okulula, ukusetshenziswa okulula, intengo ephansi, ukulinganisa okusheshayo, kanye nokufunda ngokuqondile amanani obulukhuni. Isihloli sokuqina kwe-Rockwell esingaphezulu singasetshenziswa ukuthola ngokushesha nangokungabhubhisi amaqoqo ezicubu eziphathwe ukushisa okungaphezulu ngayinye ngayinye. Kubaluleke kakhulu ezimbonini zokucubungula insimbi kanye nokukhiqiza imishini. Lapho ungqimba oluqinile lwe-Rockwell olungaphezulu luwugqinsi, isihloli sokuqina kwe-Rockwell singasetshenziswa futhi. Lapho ubukhulu bengqimba yokuqina kwe-heat treatment bungu-0.4-0.8mm, isikali se-HRA singasetshenziswa. Uma ukujula kwengqimba eqinile Uma idlula u-0.8mm, isikali se-HRC singasetshenziswa. Amanani amathathu ajwayelekile obulukhuni be-Vickers, Rockwell kanye ne-Rockwell angaphezulu angaguqulwa kalula abe ngamanye, aguqulwe abe amazinga, imidwebo noma amanani obulukhuni adingekayo ngabasebenzisi, futhi ithebula lokuguqulwa elihambisanayo liku-ISO ejwayelekile yamazwe ngamazwe. I-ASTM ejwayelekile yaseMelika kanye ne-GB/T ejwayelekile yaseShayina inikezwe.

(3) Uma ubukhulu besendlalelo esiqiniswe ngokushisa bungaphezu kuka-0.2mm, kungasetshenziswa umhloli wokuqina we-Leeb, kodwa kudingeka kukhethwe inzwa yohlobo lwe-C. Lapho kulinganiswa, kufanele kuqashelwe ukuqeda okungaphezulu kanye nobukhulu obuphelele bento yokusebenza. Le ndlela yokulinganisa ayinayo i-Vickers ne-Rockwell Umhloli wokuqina unembile, kodwa ufanelekile ukulinganiswa endaweni efektri.

2 ukwelashwa ngokushisa kwamakhemikhali

Ukwelashwa ngokushisa kwamakhemikhali kuwukufaka ingxenye engaphezulu yomsebenzi ngama-athomu ento eyodwa noma eziningana zamakhemikhali, ngaleyo ndlela kushintshe ukwakheka kwamakhemikhali, isakhiwo kanye nokusebenza kwendawo engaphezulu yomsebenzi. Ngemva kokucima kanye nokushisa okuphansi, ingxenye engaphezulu yomsebenzi iba nobunzima obukhulu kanye nokumelana nokuguguleka, kanye namandla okukhathala okuxhumana, kanti umongo womsebenzi unamandla aphezulu kanye nokuqina. Amapharamitha obuchwepheshe ayinhloko womsebenzi wokwelashwa ngokushisa kwamakhemikhali ukujula kwesendlalelo esiqinile kanye nobunzima obungaphezulu. Ibanga lapho ubulukhuni buwela khona ku-50HRC ukujula kwesendlalelo esiqinile esisebenzayo. Ukuhlolwa kobulukhuni obungaphezulu kwezinto zokusebenza eziphathwe ngokushisa kwamakhemikhali kufana nokuhlolwa kobulukhuni kwezinto zokusebenza eziphathwe ngokushisa okungaphezulu. Abahloli bobulukhuni beVickers, abahloli bobulukhuni beRockwell noma abahloli bobulukhuni beRockwell bangasetshenziswa. Umhloli wobulukhuni ukuthola, ubukhulu be-nitriding kuphela obuncane, ngokuvamile abudluli ku-0.7mm, khona-ke umhloli wobulukhuni beRockwell akakwazi ukusetshenziswa

3. ukwelashwa kokushisa kwendawo

Uma izingxenye zokwelapha ukushisa kwendawo zidinga ubulukhuni bendawo obuphezulu, ukwelashwa kokushisa kokucima kwendawo kungenziwa ngokufudumeza kokungeniswa, njll. Izingxenye ezinjalo ngokuvamile zidinga ukumaka indawo yokwelashwa kokushisa kokucima kwendawo kanye nenani lobulukhuni bendawo emdwebeni, futhi ukuhlolwa kobulukhuni bezingxenye kufanele kwenziwe endaweni ekhethiwe, ithuluzi lokuhlola ubulukhuni lingasebenzisa umhloli wobulukhuni beRockwell ukuhlola inani lobulukhuni be-HRC. Uma ungqimba oluqinisiwe lokwelashwa kokushisa lungajulile, umhloli wobulukhuni weRockwell ongaphezulu ungasetshenziswa ukuhlola inani lobulukhuni be-HRN

Isikhathi sokuthunyelwe: Agasti-16-2023